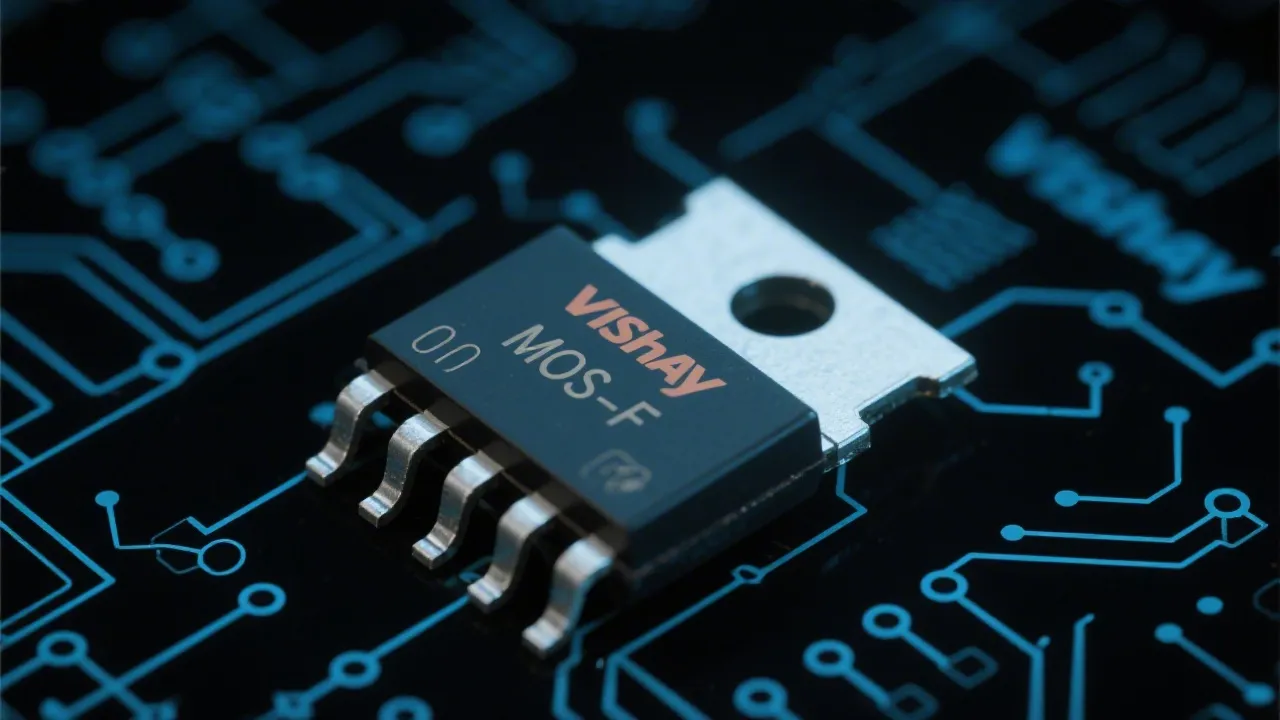

This guide delves into the intricacies of Vishay Mosfet technology, highlighting its essential role in modern electronics and its widespread applications. Known for innovating high-performance semiconductor components, Vishay's Mosfets are integral to numerous electrical and electronic designs, offering benefits such as improved efficiency, reduced energy consumption, and enhanced thermal performance.

The Vishay Mosfet represents a cornerstone of modern semiconductor devices, widely deployed across various electronic applications due to its efficiency and reliability. A crucial component in many systems, these transistors manage voltage and power by facilitating the control of electrical current flow in a compact package. The combination of rapid advancement in technology alongside an increase in consumer demand for higher efficiency electronics has propelled Vishay Mosfets into a central role in contemporary electronic design.

Vishay Mosfets are invaluable due to their exceptional efficiency in power management, forming integral parts of power supplies, motor controllers, and amplifier circuits. Their ability to handle high power levels while maintaining minimal heat generation makes them ideal for compact electronic devices that demand both performance and efficiency. Additionally, their versatility allows them to be used in a variety of configurations, which broadens their utility across diverse applications. They can also be configured in parallel or series configurations, enabling designers to tailor performance characteristics to meet specific needs.

Vishay Mosfets find applications in numerous sectors including consumer electronics, automotive systems, industrial machinery, and renewable energy systems. Their built-in capabilities, such as fast switching speeds, low on-resistance, and high thermal stability, confer advantages in creating efficient and reliable products that are pivotal in reducing the overall energy footprint. In consumer electronics, for example, they are frequently deployed in devices such as smartphones and laptops, enhancing battery life and performance. In industrial settings, Vishay Mosfets can control large motors with precision, enabling better energy management and operational efficiency, which in turn translates to cost savings over lifecycles.

Selecting an appropriate Vishay Mosfet entails considering factors such as voltage ratings, current capacity, switching speed, and thermal performance. These considerations ensure that the chosen device aligns with the specific requirements of the intended application, maximizing both performance and longevity. Furthermore, understanding the electrical characteristics such as gate threshold voltage, package type, and stability over varying frequencies can greatly influence the effectiveness of a Mosfet in a given circuit. Conducting simulations and utilizing resources provided by Vishay can assist engineers in making informed decisions, ensuring that their designs are not only functional but also efficient and cost-effective.

| Features | Description |

|---|---|

| Low On-Resistance | Ensures efficient current conduction with minimal energy loss, thereby improving overall system efficiency. |

| Fast Switching | Allows for responsive performance in dynamic electronic environments, enabling circuits to operate at higher frequencies without performance degradation. |

| Thermal Performance | Maintains stability under varying thermal conditions, enhancing device lifespan and reducing the risk of thermal breakdowns. |

| Compact Design | Facilitates the integration into space-constrained electronic assemblies, crucial for modern devices that prioritize miniaturization. |

Vishay continues to innovate within the Mosfet market, integrating advanced materials and designs to meet evolving demands for higher power density and efficiency. The market trends towards energy-efficient devices and greener technologies propel Vishay Mosfets to the forefront of industry solutions, offering sustainable advancements for future-ready systems. With the rise of electric vehicles, for example, there is a growing need for highly efficient power conversion systems that can handle rapid charging without overheating. Vishay's latest advancements in these technologies are focused on developing Mosfets that can sustain higher voltages and currents, which are essential for automotive applications.

The pathway to developing next-generation Vishay Mosfets involves an intricate innovation cycle that incorporates feedback from various markets and applications. This cycle can be broken down into several key phases:

The shift towards environmentally friendly technologies has spurred efforts within Vishay to enhance the sustainability of their manufacturing processes and products. The following arena highlights key areas where Vishay is making strides:

To illuminate the practical applications and benefits of Vishay Mosfets, several case studies exemplify their effectiveness across different industries:

In the renewable energy sector, Vishay Mosfets have proven pivotal in solar inverter applications. These inverters convert direct current (DC) generated by solar panels into alternating current (AC) for use in homes and the grid. By implementing high-performance Vishay Mosfets, manufacturers have reported significant improvements in energy conversion efficiency, reducing energy losses and improving the overall return on investment for solar installations.

In electric vehicles (EVs), effective power management is essential for performance and battery life. Vishay Mosfets are utilized in power conversion systems that drive electric motors and control battery charging. Their low on-resistance characteristics minimize losses during operation, which enhances vehicle range and performance. Automotive manufacturers employing Vishay components have observed improvements in energy efficiency, effectively addressing consumer demands for extended battery life.

In industrial applications, Vishay Mosfets facilitate robust motor control systems that are critical for machinery and automation processes. A leading manufacturer of robotics integrated Vishay Mosfets into their motor control drivers, resulting in increased responsiveness and reduced energy consumption. This transition not only improved operational efficiency but also allowed for greater design flexibility and minimized heat generation during prolonged use.

In the consumer electronics sector, Vishay Mosfets have gained traction in smartphone and laptop designs. A prominent mobile device manufacturer leveraged Vishay Mosfets to optimize the power management integrated circuits in their newest models, resulting in longer battery life despite carrying multiple demanding applications. This improvement directly addressed market demands for higher performance without increasing device sizes.

In conclusion, through constant innovation, Vishay Mosfet components remain at the forefront of efficient power management technologies, addressing both current performance needs and contributing to future advancements in the electronics domain. Their impressive specifications and adaptability make them indispensable in a world striving for technological sustainability and excellence. The ongoing commitment to enhancement and integration of cutting-edge technology ensures that Vishay will continue to meet and exceed the expectations of modern electronic applications. As society's reliance on sophisticated electronic devices grows, so too will the demand for the advanced capabilities that Vishay Mosfets provide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!