The Rexroth 7291 is a significant component in the realm of hydraulic systems, known for its efficiency and reliability. This comprehensive analysis delves into its functionalities, application areas, and benefits. As a part of Bosch Rexroth's lineup, it exemplifies advanced engineering, providing solutions across various industrial sectors, ensuring seamless operations and precision management.

In the world of hydraulics, the Rexroth 7291 stands as a beacon of innovation and engineering excellence. Part of the illustrious Bosch Rexroth family, it epitomizes reliability and efficiency, crucial for diverse industrial applications. Professionals and engineers rely on such components to ensure that machinery operates smoothly and effectively. The Rexroth 7291 has been specifically designed to meet the high demands of industrial tasks while ensuring operators can maintain optimal performance levels.

The evolution of hydraulic technology has paved the way for advanced components like the Rexroth 7291. As industries grow and machinery becomes more complex, hydraulic systems become increasingly vital in maintaining the productivity and effectiveness of operations. This hydraulic component not only meets existing requirements but also anticipates future needs, embedding adaptability into its design and functionality.

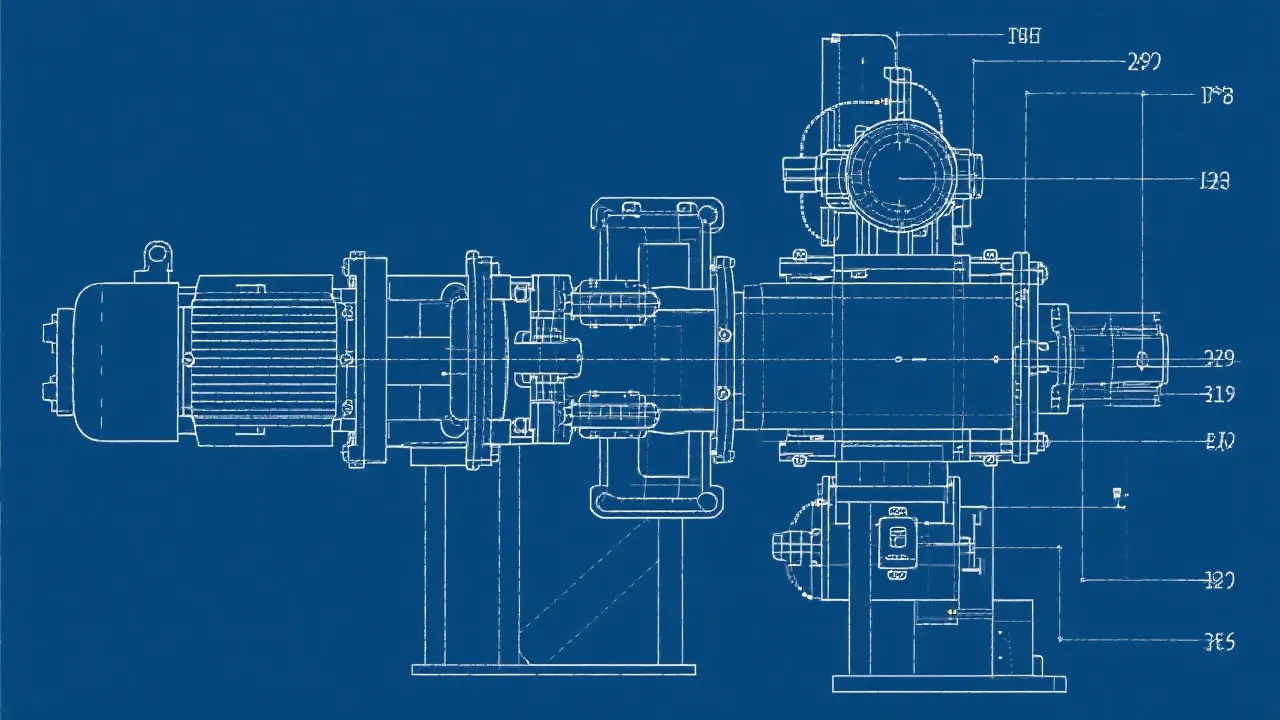

The Rexroth 7291 is designed to handle complex hydraulic processes, combining durability with exceptional performance. Here are some key features:

The advancements in hydraulic technology represented by the Rexroth 7291 are instrumental for industries seeking to enhance productivity and operational efficacy. Its features are designed with the end-user in mind, ensuring that functionality aligns with the practical needs of the workplace. Beyond just improving efficiency, the Rexroth 7291 also addresses common challenges faced in hydraulic system management, contributing to a streamlined operational flow.

The specifics of the Rexroth 7291 reinforce its suitability for heavy-duty applications:

The applications of the Rexroth 7291 are extensive, and its design philosophy reflects the imperative for components to serve multiple functions across various settings. Whether it is used in a construction site where hydraulic presses lift heavy materials or in automotive plants that require reliable hydraulic steering systems, the Rexroth 7291 proves its worth through varied applications. This adaptability enhances its market viability, allowing it to remain an industry leader in hydraulic technology.

By leveraging the capabilities of the Rexroth 7291, industries not only enhance operational efficiency but also ensure environmental compliance due to its energy-efficient design. It symbolizes progressive movement in reducing carbon footprints without compromising on performance. The efficiency of the Rexroth 7291 resonates with industrial goals of sustainability, proving that advancements in technology can align with ecological responsibility.

Industries utilizing the Rexroth 7291 are often better positioned to meet regulatory standards concerning emissions and energy consumption. As organizations face increasing pressure to adopt sustainable practices, the Rexroth 7291 offers a practical solution that both supports operational needs and helps fulfill corporate social responsibilities. The impact on the environment is not just a matter of compliance but also a strategy for long-term viability in a rapidly changing market landscape.

| Parameter | Rexroth 7291 | Competitor A | Competitor B |

|---|---|---|---|

| Efficiency (%) | 95 | 90 | 88 |

| Durability (years) | 10 | 8 | 7 |

| Temperature Range (°C) | -20 to 80 | -15 to 70 | -10 to 65 |

The comparative analysis provided above highlights the superior features of the Rexroth 7291 in a competitive landscape. Its exceptional efficiency and durability make it a preferred choice for industries facing rigorous demands. In a sector that often requires quick and lasting solutions, the Rexroth 7291 not only meets but exceeds expectations.

Furthermore, the temperature tolerance of the Rexroth 7291 allows it to outperform its competitors in extreme environments. This feature provides a significant advantage in applications where other hydraulic components might fail, leading to costly downtimes and inefficiencies. In contexts such as offshore drilling or mining, where temperature and pressure conditions can vary dramatically, the Rexroth 7291 demonstrates reliability that is crucial for sustained performance.

From an academic viewpoint, the Rexroth 7291 has been a subject of numerous studies emphasizing its robustness and adaptability in industrial processes. Researchers often cite its superior engineering as a benchmark for evaluating newer hydraulic technologies. The focus on performance metrics, energy efficiency, and environmental impact makes the Rexroth 7291 an intriguing subject for academic inquiries aiming to understand the trajectory of hydraulic design and engineering.

Many studies explore the ways in which the Rexroth 7291 integrates advancements such as smart technology and IoT capabilities into its framework. As industries increasingly rely on data analytics and interconnected systems, understanding how such hydraulic components can work within these environments is essential. The discussion expands beyond mere technical specifications into the realm of digital processes and the adoption of Industry 4.0 principles, showcasing how the Rexroth 7291 is not just a mechanical component, but part of a larger movement towards intelligent manufacturing systems.

In addition to these FAQs, it's important to note how maintenance practices affect the performance and longevity of the Rexroth 7291. Proper maintenance schedules, including regular checks and fluid quality control, can significantly enhance the efficacy of hydraulic systems equipped with the Rexroth 7291. This proactive approach ensures that the system operates at peak performance and can anticipate and prevent potential failures that could lead to interruptions.

In conclusion, the Rexroth 7291 is a pivotal innovation in the field of industrial hydraulics. Its extensive applicability, coupled with unparalleled performance metrics, positions it as a leader in the hydraulic components market. This hydraulic unit not only meets the pressing demands of modern industries but also sets standards for future development in hydraulic technology.

With ongoing advancements in technology, future iterations hold the promise of even greater efficiency and integration into intelligent systems, heralding a new era in industrial hydraulics. As manufacturers explore incorporating artificial intelligence and machine learning into their processes, components like the Rexroth 7291 will likely evolve alongside these trends, offering more sophisticated monitoring and management features that can enhance operational transparency and data-driven decision-making.

The future of hydraulic components, particularly the Rexroth 7291, lies in its ability to adapt to advancements in technology while maintaining core functionality and reliability. The marriage of hydraulic mechanics with digital intelligence will surely redefine industry standards and expectations, fostering a new generation of hydraulic systems that are not only efficient but also smart and responsive to user needs. As businesses strive to stay ahead in competitive markets, the relevance of such innovations cannot be overstated, ensuring that the Rexroth 7291 and its successors remain at the forefront of industrial progress.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!