The Rexroth 7291 is a critical component in industrial hydraulic systems, used globally for its reliability and efficiency. Known for improving machine productivity, the 7291 offers exceptional performance in various applications. This guide delves into its significance, industry applications, and technical intricacies, providing insight from an expert perspective.

In the realm of industrial engineering, the Rexroth 7291 stands as a benchmark for reliability and performance. Designed by Bosch Rexroth, a leader in drive and control technology, this component plays an indispensable role in various hydraulic systems worldwide. Known for its precision and durability, the Rexroth 7291 has become synonymous with high efficiency and operational excellence.

The Rexroth 7291 distinguishes itself with several critical features that contribute to its widespread adoption. Its robust design ensures longevity even under strenuous operating conditions. The rigorous testing processes, including simulations and real-world applications, validate its performance across different scenarios, making it a favorite among engineers and operators alike.

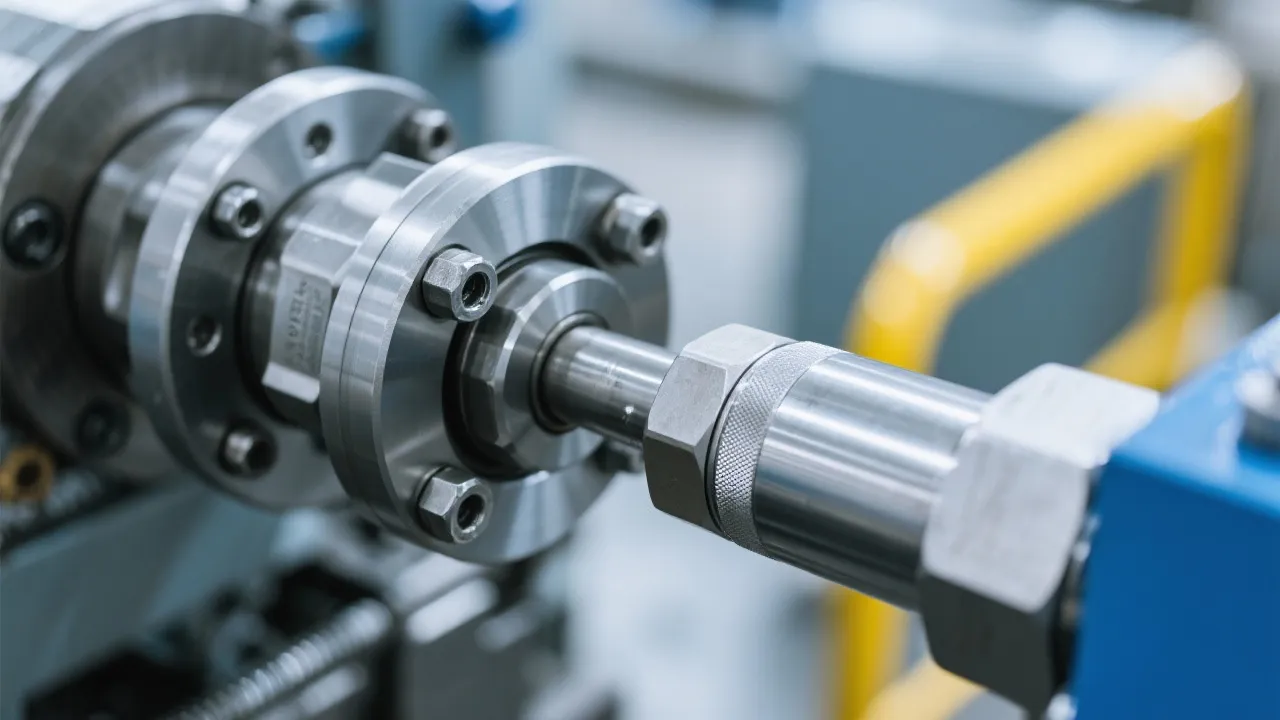

In addition to its structural advantages, the precision engineering behind the product facilitates optimal performance, significantly enhancing the efficiency of hydraulic systems. The product is crafted using advanced manufacturing techniques that improve its reliability, such as CNC machining, which allows for tolerances that exceed industry standards. This precision is complemented by careful selection of materials, ensuring that each unit can withstand corrosive environments, high pressures, and variable temperatures.

The component's adaptability across different applications further solidifies its standing in the industry. It is designed to accommodate a variety of hydraulic fluids, which makes it versatile enough to serve in everything from oil rigs to agricultural machinery. This flexibility enables users to appreciate seamless integration and performance consistency, regardless of the specific conditions under which it operates.

Industries ranging from manufacturing to construction find the Rexroth 7291 indispensable due to its capability to manage high-pressure operations smoothly. It provides optimized motion control, which is imperative for maintaining productivity and safety in environments such as factory automation, heavy machinery, and material handling systems. Moreover, the design of the Rexroth 7291 allows for easy maintenance and repair, which is crucial in industries where uptime is critical.

In manufacturing settings, the Rexroth 7291 is often integrated into automated assembly lines where precise movements are crucial. For instance, in automobile manufacturing, the component helps in controlling robotic arms that must operate with both speed and accuracy, ensuring that assemblies are completed without error. Similarly, in construction, it aids in operating cranes and lifts, where the precise control of heavy loads is vital for safety and efficiency.

The component's precise control mechanisms support intricate operations, thereby reducing error margins and downtime. By implementing this technology, industries can realize significant productivity gains, ultimately leading to higher profitability. Additionally, the Rexroth 7291 supports retrofitting existing equipment, making it a cost-effective solution focused on upgrading performance without the need for complete replacements.

What sets Rexroth 7291 apart is its integration of cutting-edge technology and engineering expertise. Utilizing advanced materials and design methodologies ensures superior performance. Bosch Rexroth’s commitment to research and development keeps it at the forefront of innovation, providing customers with products that not only meet current industrial demands but are also future-proof.

Innovative features include real-time monitoring capabilities, where sensors integrated into the Rexroth 7291 can collect data on performance metrics such as temperature, pressure, and system vibrations. This data is valuable for predictive maintenance, allowing industries to foresee potential failures, thus minimizing downtime and repair costs. Incorporating IoT capabilities, the Rexroth 7291 communicates with other devices in a smart factory setup, enhancing overall operational efficiency.

Furthermore, consistent innovation in its development underscores Bosch Rexroth’s commitment to sustainability and operational efficiency. Projects are geared towards minimizing energy consumption while maximizing output, addressing the dual challenges of efficiency and environmental responsibility. The production processes are aligned to meet stringent environmental regulations, focusing on eco-friendly materials and sustainable practices that contribute to a reduced carbon footprint.

| Attribute | Rexroth 7291 | Competitor Products |

|---|---|---|

| Durability | High durability with robust materials | Varies, often lesser longevity |

| Efficiency | Superior operational efficiency | Good, but often less optimized |

| Application Range | Highly versatile across industries | Often limited to specific uses |

| Innovation | Continuous technological advancements | Lagging in innovation |

| Support and Distribution | Global network of certified distributors | Limited support options |

This comparative analysis highlights the Rexroth 7291's position as the superior choice for industries seeking high-performance hydraulic components. The durability of the Rexroth 7291 is often unmatched, as it remains operational under extreme conditions where competing products may fail, leading to costly downtime. The range of applications that the Rexroth 7291 can serve makes it a go-to solution for engineers looking to enhance productivity across various sectors.

Moreover, Bosch Rexroth offers extensive support for Rexroth 7291 users, including a global network of certified distributors who provide product training, installation assistance, and after-sales service. This level of support is essential in maintaining the efficiency of industrial operations and is a key consideration for companies when choosing hydraulic components.

In a multi-faceted industrial environment, the harmony between drive systems and hydraulic systems is paramount. The Rexroth 7291 exemplifies this synergy, offering seamless integration with existing setups and ensuring smooth workflow transitions. Its role in modernizing and upgrading industrial facilities cannot be overstated, as it translates into significant cost savings and enhanced operational capacity.

Drive systems function by converting various forms of energy into mechanical energy to drive machinery. The integration of hydraulic systems, such as those utilizing the Rexroth 7291, amplifies this operational capability. These systems work in tandem to optimize efficiency; for instance, in material handling operations, hydraulic lifts powered through the Rexroth 7291 can load and unload components with precision, drastically reducing time spent in manual handling and increasing throughput.

The scalability of the Rexroth 7291 also allows it to adapt to evolving production demands. As businesses grow or pivot their operations, incorporating additional Rexroth components or upgrading existing setups becomes straightforward. This forward-thinking design aligns with lean manufacturing principles that prioritize waste reduction and efficiency enhancement, making the Rexroth 7291 a pivotal component in this strategy.

Additionally, advancements in control technology paired with the hydraulics of the Rexroth 7291 allow for enhanced safety features in machinery operations. The benefits not only impact productivity but also worker safety. Many operations incorporate fail-safe systems, which automatically cease operation when anomalies are detected, providing peace of mind to employers and employees alike.

What is the primary application of Rexroth 7291?

The Rexroth 7291 is mainly used in hydraulic systems for its robust performance and efficiency, suitable for industries like manufacturing and construction. Its adaptability allows it to serve in numerous applications from line automation to heavy machinery.

How does Rexroth 7291 enhance machine productivity?

By providing precise motion control and high durability, the Rexroth 7291 enhances productivity by minimizing downtime and reducing error margins. This leads to smoother operations and ensures that machinery consistently operates at peak performance, especially during complex tasks requiring high accuracy.

Is the Rexroth 7291 environmentally friendly?

Yes, Bosch Rexroth has incorporated sustainable practices in the design of the Rexroth 7291, aiming to meet environmental standards and reduce carbon footprints. The selection of materials considers ecological impact, and manufacturing processes are designed to minimize waste, promoting a more sustainable industrial footprint.

Who can supply Rexroth 7291?

Rexroth products, including the 7291, are available through certified Bosch Rexroth distributors worldwide, ensuring product authenticity and support. This supply chain guarantees users receive high-quality products accompanied by professional backing for installation and maintenance needs.

Unwavering in its performance, the Rexroth 7291 represents the pinnacle of precision and reliability in hydraulic components. Its integration into industrial systems not only yields improved productivity but also ensures sustainability and future readiness. As industries continue to evolve, the Rexroth 7291 remains a constant in innovation and excellence, earning its place as a trusted ally in the quest for industrial advancement.

As the landscape of industrial engineering continues to change with the advent of technology—including automation and IoT—the demand for advanced, efficient systems like the Rexroth 7291 will only grow. With ongoing developments in the field, Bosch Rexroth is committed to pushing the boundaries of what is possible, ensuring that their customers can remain competitive in an ever-evolving market. The future of the Rexroth 7291 is promising, with a focus on further integrating smart technology into hydraulic systems, paving the way for a new era of industrial efficiency.

Ultimately, the Rexroth 7291 not only enhances current applications but also inspires future innovations, making it a cornerstone around which modern industrial practices can evolve. As technology advances and the need for higher efficiency continues to drive industry standards, the Rexroth 7291 will undoubtedly remain at the forefront of hydraulic solutions, redefining what is possible for engineers and operators across the globe.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!