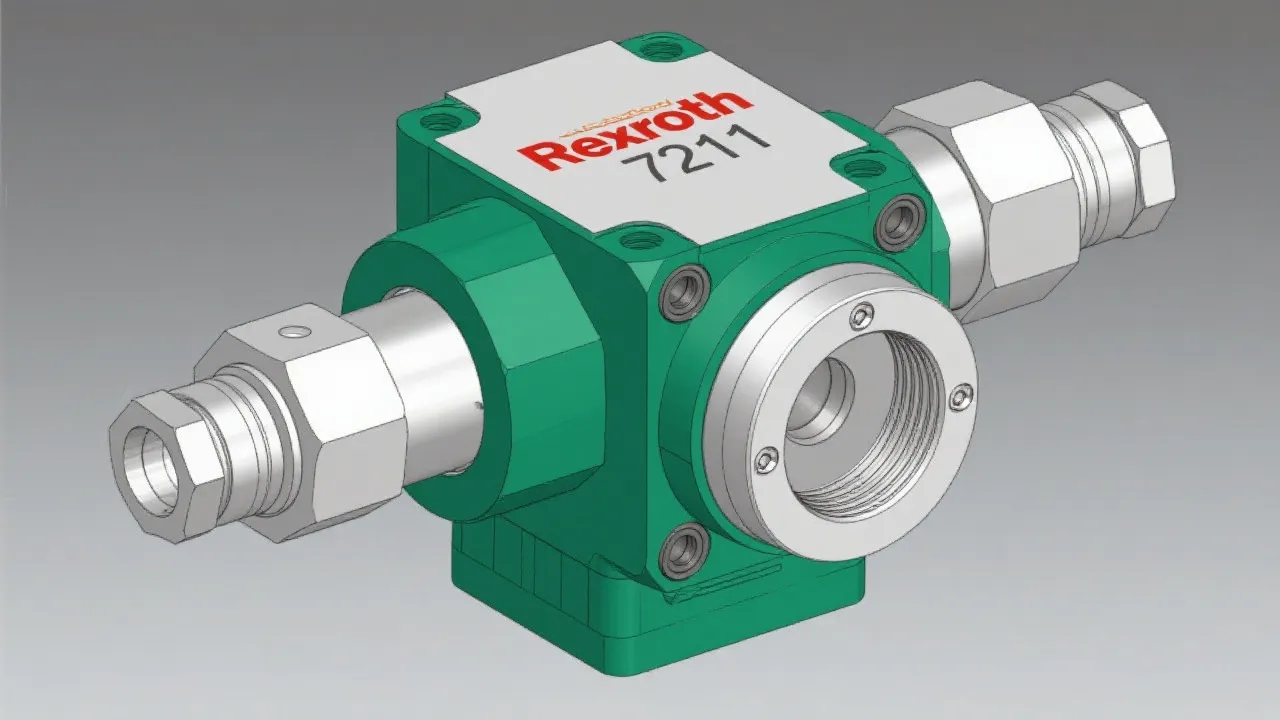

Rexroth 7291 is a high-performance hydraulic component known for its reliability and precision in industrial applications. It forms a crucial part of Bosch Rexroth’s offerings, a leader in drive and control technologies. This article delves into the various aspects of Rexroth 7291, including its applications, benefits, and expert insights into its operation and optimization.

The Rexroth 7291 represents the pinnacle of hydraulic technology, utilized in various industrial sectors for its robust performance and precision. Manufactured by Bosch Rexroth, a global leader in drive and control technologies, the 7291 series is integral in ensuring efficient and reliable operation in complex hydraulic systems. This article explores the diverse applications, benefits, and operational insights of the Rexroth 7291, providing industry expertise for those seeking to understand its value.

Designed with the demands of modern industries in mind, the Rexroth 7291 series integrates seamlessly into various applications, ensuring that users achieve their desired outcomes efficiently. Beyond just its core functionality, the series embodies the principles of innovation and engineering excellence that Bosch Rexroth is known for. With the rapid advances in technology and the increasing complexity of operations, the importance of having reliable hydraulic components like the Rexroth 7291 cannot be overstated, making this overview essential for professionals in the field.

Rexroth 7291 components are predominantly used in heavy machinery, manufacturing plants, and automation systems. Their ability to provide consistent performance under high pressure makes them ideal for tasks requiring precise fluid control. Industries such as automotive manufacturing, mining, and marine operations greatly benefit from the robustness and adaptability of the 7291 series.

In automotive manufacturing, the Rexroth 7291 is pivotal for ensuring that hydraulic systems in assembly lines operate flawlessly. This includes everything from stamp presses and robotic arms to hydraulic lifts, where precision and reliability are critical. For example, consider the hydraulic systems in robotic welding machines. They rely on precise movements to weld components together flawlessly; any failure could lead to scrap parts and financial loss.

Mining operations utilize the Rexroth 7291 for powering equipment like excavators and drills. These machines face demanding conditions, including extreme pressure and abrasive materials. The Rexroth 7291 series is engineered to withstand these conditions without succumbing to performance degradation, which is vital in ensuring continuous operations and enhancing productivity.

Additionally, in marine applications, where equipment is frequently exposed to harsh environments, the corrosion resistance and durability of the Rexroth 7291 contribute significantly to operational efficiency. From hydraulic steering systems on vessels to the operation of cranes in port facilities, the adaptability of the 7291 across such diverse applications highlights its value within the industry.

The Rexroth 7291 is renowned for its durability, precision, and easy integration into existing systems. Key features include advanced sealing technology that minimizes leakage, superior material quality for extended lifespan, and a modular design that allows for seamless customization. These benefits translate into reduced maintenance costs, enhanced performance efficiency, and reliable operation across various demanding environments.

One of the standout features of the Rexroth 7291 series is its advanced sealing technology. Leaks in hydraulic systems can lead to operational inefficiencies, increased maintenance costs, and environmental hazards. The 7291's design includes state-of-the-art seals that provide superior resistance to wear and tear, ensuring minimal leakage during operation. This is critical for industries where fluid control directly affects production quality and safety.

Moreover, the material quality used in the construction of Rexroth 7291 components is paramount. These components are made from high-grade steel, which not only enhances their strength but also their resistance to corrosive agents and harsh operating conditions. This robustness directly correlates with the component’s lifespan, reducing the frequency of replacements and fostering longer operational cycles.

The modular design of the Rexroth 7291 is another aspect worthy of exploration. It allows operators to customize their hydraulic systems easily, adapting to specific operational needs without requiring complete system overhauls. This flexibility is essential in dynamic industries where operational requirements can change rapidly. By enabling straightforward integration of new components, the 7291 helps businesses maintain productivity without sacrificing performance.

Industry experts highlight the importance of proper installation and maintenance to maximize the benefits of Rexroth 7291 components. Regular system audits and use of genuine parts can significantly extend the life of the components and optimize overall system performance. Bosch Rexroth offers training and support to ensure users fully understand the capabilities and optimal handling of the 7291 series.

In many cases, proper installation is underestimated, yet it is critical for ensuring the long-term effectiveness of hydraulic components. Neglecting installation best practices can lead to premature failure, necessitating costly repairs and downtime. Experts recommend that trained personnel carry out installations, ensuring that all components are aligned and secured correctly. This process not only involves the initial setup but also understanding the specific parameters of the hydraulic system, such as pressure settings and flow rates.

Regular maintenance checks are another essential element for keeping Rexroth 7291 components functioning at peak efficiency. This includes not only visual inspections for wear and tear but also thorough testing of hydraulic fluids and seals. Bosch Rexroth provides comprehensive guidelines and support for maintenance practices, empowering operators to perform audits effectively. Through the implementation of predictive maintenance strategies, operators can anticipate potential failures before they occur, significantly enhancing overall operational reliability.

| Model | Pressure Rating | Material | Applications |

|---|---|---|---|

| Rexroth 7291 | High | Steel | Heavy Machinery, Manufacturing, Mining, Marine |

| Rexroth 6120 | Medium | Aluminum | Light Industrial, Automation |

| Rexroth 7200 | High | Stainless Steel | Food Processing, Pharmaceutical |

| Rexroth 7000 | Low | Plastic | Packaging, Textile |

This comparison highlights not only the specifications of the Rexroth 7291 but also shows how it stacks up against other models in the Rexroth lineup. While the 6120 series caters effectively to lighter industrial applications with lower pressure requirements and aluminum construction for weight savings, the 7291 is fortified to handle the rigors of heavy-duty tasks. By examining these aspects, operators can make informed choices based on their operational needs.

What industries commonly use Rexroth 7291 components? These are typically used in automotive, mining, and marine industries due to their reliability in high-pressure environments. Additionally, industries such as construction, aerospace, and energy generation also depend significantly on the performance and durability offered by the Rexroth 7291 series in their complex hydraulic systems.

How does Rexroth 7291 enhance operational efficiency? With its advanced sealing technology and modular design, it reduces leakage and maintenance needs, improving system efficiency and uptime. Moreover, the quality of materials used ensures that the components resist wear over prolonged operational cycles, allowing industries to experience increased output without the concern of frequent repairs.

Where can I find support for Rexroth 7291 products? Bosch Rexroth provides comprehensive support, including training and genuine parts supply, ensuring optimal product integration and use. Their technical support services include troubleshooting, system design assistance, and consultation on best practices, which are invaluable for ensuring sustained high performance from hydraulic systems.

The Rexroth 7291 continues to set the standard in hydraulic components, offering unmatched precision and durability. As industries push towards more automated and efficient operations, such components play a crucial role in achieving productivity and sustainability goals. With the backing of Bosch Rexroth's expertise and support infrastructure, users can leverage the full potential of the 7291, ensuring optimal functionality and longevity in their hydraulic systems.

The focus on performance needs to be coupled with a commitment to sustainability. Rexroth's advanced technologies in the 7291 series not only optimize hydraulic system performance but also contribute to reduced energy consumption and less fluid wastage, aligning with global efforts towards environmentally responsible manufacturing practices. The implications of adopting such technologies reverberate through the entire supply chain, showcasing how smart investments in superior hydraulic components can yield measurable benefits in both operational output and corporate responsibility.

As we look to the future, the continued evolution of hydraulic technologies will likely see the integration of smart capabilities, enabling further enhancements in automation and data-driven decision-making within hydraulic systems. The Rexroth 7291 stands at the forefront of this movement, exemplifying how innovation in hydraulic technology is not just about meeting today's demands but also anticipating the needs of tomorrow's industries.

Overall, understanding the Rexroth 7291 and its applications within the broader context of hydraulic systems empowers professionals to make informed decisions that leverage these enhanced hydraulic technologies. Whether through improving efficiency, achieving cost savings, or enhancing safety and reliability in operations, the Rexroth 7291 is an invaluable asset across numerous sectors, facilitating a path towards future advancements in hydraulic technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!