The article explores Rexroth Modular Valves, key components used in hydraulic systems to control fluid flow and pressure. Known for their efficiency and flexibility, these valves support a variety of industrial applications across sectors. Understanding their functionality and benefits is essential for optimizing hydraulic systems. The article delves into their technical aspects, advantages, and the potential impact on operational productivity.

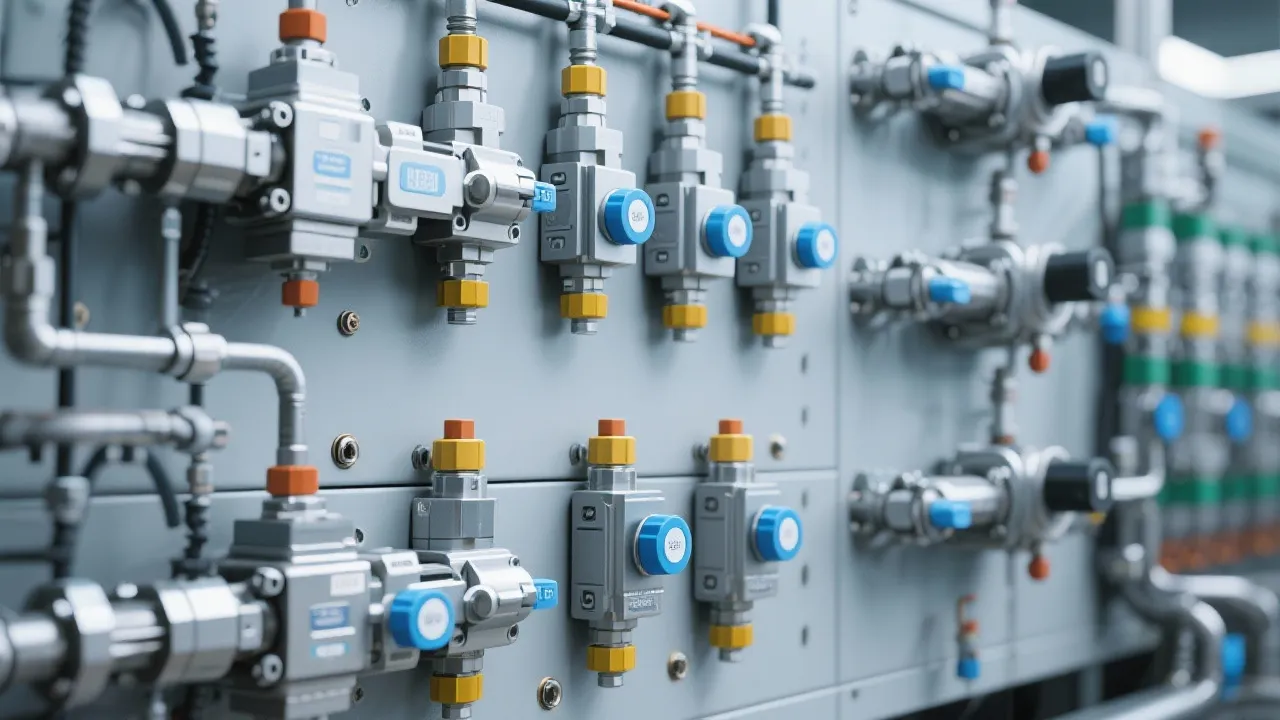

Rexroth Modular Valves are integral to the efficiency and customization of modern hydraulic systems. These valves, designed by Bosch Rexroth, are renowned for their modularity, allowing for easy integration into complex hydraulic circuits. They provide precise control of flow and pressure, making them indispensable in industries ranging from manufacturing to automotive and aerospace. With advancements in automation and the need for energy-efficient solutions, these valves come at the forefront of hydraulic technology.

The standout feature of Rexroth Modular Valves is their versatility. Designed for stacking configurations, they enable system designers to build tailored hydraulic circuits without extensive pipework. This modular approach not only saves space but also reduces potential leakage points and installation time, translating into cost-effective solutions for businesses. Furthermore, the ability to swap components in and out allows for easy upgrades, ensuring that the hydraulic systems can evolve as operational needs change. This level of flexibility isn't just beneficial; it leads to increased innovation within the industry, as engineers can experiment with different setups quickly and efficiently.

These valves incorporate advanced materials and engineering to withstand extreme conditions. The precision machining of components ensures reliable performance and long service life. Additionally, the use of high-quality seals and robust housing materials contributes to the valves' durability under high-pressure conditions. Advanced lubrication techniques are often employed to further enhance operational life, while coatings are utilized to prevent corrosion, ensuring that these valves maintain their integrity in harsh environments. The technical sophistication behind each component optimizes functionality and performance, resulting in a hydraulic system that operates seamlessly under varying loads and pressures.

Rexroth Modular Valves find usage in various applications such as material handling systems, industrial manufacturing processes, and mobile machinery. Their ability to maintain consistent, accurate pressure and flow control enhances the performance of equipment in these sectors. Below is a detailed look at their applications in different industries:

| Industry | Application |

|---|---|

| Automotive | Assembly lines for vehicle manufacturing, including robotic arms and part handling systems where precise control is crucial. |

| Aerospace | Hydraulic control systems for aircraft involving landing gear, flaps, and thrust vectoring systems that require fail-safe mechanisms. |

| Construction | Hydraulic systems in earth-moving equipment like excavators and loaders, ensuring robust power and control in rugged environments. |

| Marine | Applications in ship hydraulic systems for steering controls, stabilizers, and cargo handling operations that cope with oceanic conditions. |

| Food and Beverage | Used in bottling and packaging lines where sanitary standards are vital, ensuring precision and cleanliness in hydraulic actuation. |

| Metalworking | Hydraulic presses and shears that demand high pressures and precise operations, allowing operators to achieve perfect cuts and formations. |

Proper installation and maintenance are crucial for the optimal performance of Rexroth Modular Valves. Regular inspections and adherence to installation guidelines ensure longevity and efficiency. Maintenance typically involves checking for leakages, testing pressure calibrations, and ensuring that all fittings and connections remain secure. Given the modular design, many valves offer “plug and play” functionality, meaning that if one module fails, it can be easily replaced without disrupting the entire system.

Moreover, understanding the fluid types being used is essential. Different hydraulic fluids can have varying effects on the material components of the valves. Using inappropriate fluids can lead to premature wear or failure. Therefore, companies need to invest in training operational staff to recognize the correct procedures and best practices in handling and maintaining these components.

Rexroth's commitment to innovation is evident through the various advanced features integrated into their Modular Valves. Many of these innovations focus on enhancing the smoothness of operations, real-time data access, and increased energy efficiency. Here are some noted advancements:

Q1: What makes modular valves more effective in hydraulic systems?

A: The modular design allows for easy configurability and integration, reducing setup complexity and increasing system reliability. It provides the flexibility to add or remove components based on current and future needs without extensive reengineering.

Q2: How does Rexroth ensure the quality of its modular valves?

A: Through rigorous testing protocols and the use of premium materials, Rexroth guarantees the reliability and durability of their valves. Each product undergoes comprehensive stress testing to ensure that it meets industry standards before it reaches the market.

Q3: Are Rexroth Modular Valves suitable for harsh environments?

A: Yes, they are designed to perform under extreme conditions thanks to their robust construction and superior sealing technology. Many models feature protective coatings that enhance resistance to dust, moisture, and other harsh environmental factors.

Q4: How can I ensure my modular valve setup is efficient?

A: Regular maintenance, proper installation, and customization according to operational demands will optimize efficiency. Implementing a predictive maintenance strategy using real-time monitoring can also help identify performance drops before they lead to failures.

Q5: What industries can benefit the most from Rexroth Modular Valves?

A: Industries such as automotive, aerospace, construction, food processing, and beyond can maximize their operational efficiency by adopting Rexroth Modular Valves. Their flexibility and reliability cater to a wide array of applications.

Rexroth Modular Valves are pivotal in advancing hydraulic technology. Their flexibility, combined with efficiency in space usage and ease of maintenance, makes them a prime choice for industries aiming to enhance their operational capabilities. This adaptability is crucial as industries face ever-changing demands in production efficiency, reliability, and sustainability. For businesses to stay competitive, an investment in such innovative technology is a step towards sustainable industrial growth. As the future unfolds, it will be interesting to observe how Rexroth's continuous improvement and innovation will further shape the landscape of hydraulic systems worldwide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!