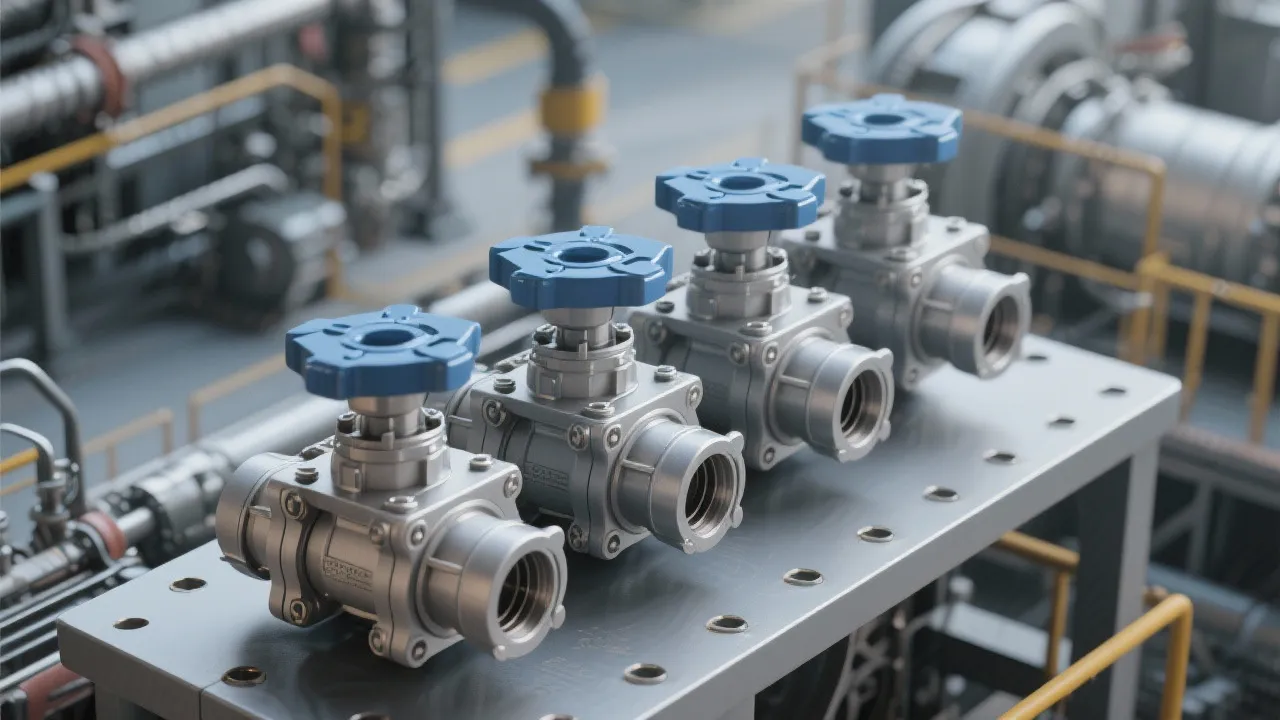

Rexroth Modular Valves play a pivotal role in hydraulic systems by allowing precise control and customization in various applications. Known for their robustness and reliability, these valves are essential components in industries ranging from manufacturing to energy. This guide delves into the technical specifics, benefits, and various configurations of Rexroth Modular Valves without highlighting the year.

An Overview of Rexroth Modular Valves

Rexroth Modular Valves have established themselves as key players in the hydraulics sector, enabling precise control and flexibility across numerous engineering applications. Their modular nature allows for efficient customization and adaptation to specific needs, making them indispensable in industries such as agriculture, manufacturing, construction, and automotive. As companies continually strive to improve efficiency and reduce costs, the demand for reliable hydraulic components that can withstand rigorous operational conditions has grown tremendously. Rexroth, with its long-standing engineering expertise, provides solutions that meet these pressing industry challenges.

The Functionality and Importance of Modular Valves

Modular valves offer a variety of control options for hydraulic circuits, including pressure, flow, and directional control. They serve as vital components in hydraulic systems, ensuring the smooth operation of machinery and preventing system failures by maintaining pressure and flow limits. The modular design of these valves makes them highly adaptable, allowing for easy integration into existing systems. This adaptability is especially crucial in production environments where machinery might need upgrading or reconfiguration to meet changing production demands. The ability to modify hydraulic circuits effectively can lead to significant cost savings and optimizations in operational efficiencies.

Technical Specifications

Rexroth Modular Valves come with several key specifications that highlight their capability:

- Pressure Rating: Typically up to 350 bar, accommodating high-pressure operations. This high pressure capacity allows for versatility in applications, from low-force operations to demanding heavy machinery operations.

- Flow Rate: Varied options to suit different application needs, ranging from low to high flow capacities. Being able to choose the right flow rate means that operators can configure the valves to suit the specific needs of their machinery, ensuring optimal performance and energy efficiency.

- Mounting: Standardized mounting patterns for ease of installation and replacement. These standardized measurements minimize installation time and help ensure compatibility with various existing systems and installations.

- Material Appropriateness: Constructed with high-quality materials such as aluminum and steel, Rexroth Modular Valves are designed for durability and reliability in harsh environments, providing long service lives even under the most demanding conditions.

- Temperature Range: Typically able to operate effectively in a wide temperature range, allowing for usage in both extreme cold and hot environments. This characteristic is essential in industries such as mining or construction, where temperature can greatly impact hydraulic fluid viscosity and performance.

- Maintenance Requirements: Low maintenance requirements, ensuring that operators can manage these components with minimal disruption to daily operations.

Benefits of Using Rexroth Modular Valves

The benefits of opting for Rexroth's offerings extend beyond the immediate functionality. These include:

- Scalability: The modularity allows for system scaling, catering to both small setups and large-scale industrial operations. This capability means that a company can start with a simpler system and gradually add more modules as their needs grow, thus future-proofing their investment.

- Cost-Effectiveness: Reduces downtime due to ease of maintenance and replacement of components. Additionally, the precise positioning and control enabled by the valves help minimize energy waste, further lowering operational costs.

- Enhanced Efficiency: Precise control mechanisms reduce energy consumption and boost system efficiency. The ability to fine-tune operations can lead to significant improvements in production rates and product quality.

- Durability and Reliability: The robust construction of Rexroth Modular Valves ensures they can withstand the rigors of various industrial applications, which means reduced frequency of replacements and repairs, thus lowering the total cost of ownership.

- Advanced Technology: Integration of cutting-edge technology in valve design allows for enhanced diagnostics and performance monitoring. This technology enables companies to address issues proactively, leading to increased uptime and overall productivity.

Available Configurations and Options

Rexroth provides various modular valves, each tailored for specific tasks and industries:

| Valve Type |

Description |

| Pressure Relief Valves |

Protect systems from overpressure by allowing fluid to flow out when pressure exceeds set limits. These valves are essential in maintaining system integrity and preventing catastrophic failures. |

| Directional Control Valves |

Direct the path of fluid within the system, enabling motion control of hydraulic actuators. Directional control valves are crucial for applications where precise movement is required, such as robotic systems and conveyor belts. |

| Flow Control Valves |

Regulate the speed and flow rate of the fluid, enabling precise system tuning. Flow control valves are vital when specific flow rates are necessary to achieve desired operational speeds in machinery. |

| Proportional Control Valves |

Allow for variable control of flow and pressure, adjusting performance levels according to input signals. They're ideal for complicated applications like mobile machinery control or systems requiring variable operation. |

| Solenoid Valves |

Electrically operated valves that control the flow of hydraulic fluid based on electromagnetic signals, offering high-speed operation and high reliability. |

Applications and Industries

Rexroth Modular Valves have a wide range of applications across various sectors, demonstrating their versatility. Below are a few key industries where these valves are making a significant impact:

- Agriculture: In modern agricultural equipment, pressure and flow control are crucial for optimal operation. Rexroth Modular Valves help control hydraulic systems in tractors, harvesters, and other farm machinery, ensuring reliable performance and enhanced productivity.

- Manufacturing: From assembly lines to automated machinery, manufacturing processes rely on precise hydraulic control for quality and efficiency. Modular valves allow manufacturers to design systems that optimize flow and pressure for specific tasks, resulting in better product quality and reduced waste.

- Construction: Heavy machinery used in construction, such as excavators and cranes, depends heavily on hydraulic systems. The modular approach of Rexroth valves ensures that these machines operate smoothly and efficiently under load, thus enhancing safety and performance on job sites.

- Automotive: In automotive manufacturing and repair, hydraulic systems are used extensively for equipment and machinery involved in assembly and testing. Rexroth Modular Valves facilitate function and precision during these critical operations.

- Aerospace: Aerospace applications require highly reliable and lightweight components, which Rexroth addresses with their modular valves, used in hydraulic systems to control movements, supplying power to various aircraft systems.

- Mining: In challenging environments such as mines, dependable hydraulic systems are paramount. Rexroth's durable modular valves can handle the extreme pressures and environmental conditions found in these applications, ensuring equipment maintains functionality.

FAQs

- Q: What industries benefit very from Rexroth Modular Valves?

- A: Industries such as manufacturing, agriculture, construction, automotive, aerospace, and mining typically see significant benefits due to the need for precise control and reliability.

- Q: Can these valves be integrated into existing systems?

- A: Yes, the modular nature and standardized mounting patterns of the valves make them highly adaptable for integration into current setups, which supports organizations in upgrading their machinery without extensive retrofitting.

- Q: How do these valves contribute to cost savings?

- A: Their design minimizes downtime and maintenance costs, offering good savings through efficiency improvements and reduced operational disruptions. Additionally, less energy is consumed during operations, further driving down costs.

- Q: What sets Rexroth Modular Valves apart from competitors?

- A: Rexroth Modular Valves are distinguished by their robust construction, extensive customization options, and proven reliability. This combination allows them to outperform competitors in demanding applications, delivering superior performance and results.

- Q: Are there any training resources available for new users?

- A: Yes, Rexroth offers several training programs, manuals, and online resources to educate users on system installation, maintenance, and optimization, ensuring they can apply their products effectively.

Conclusion

Rexroth Modular Valves embody a perfect blend of innovation and practical application, providing precise control and customization for a wide range of industries. Their robust design, coupled with adaptability and efficiency, makes them an excellent choice for improving system performance and reliability. For industries looking to optimize their hydraulic systems, Rexroth offers not just products but solutions built for today's demanding environments. As businesses face ever-increasing challenges in efficiency and reliability, the investment in Rexroth Modular Valves not only fulfills immediate operational needs but acts as a stepping stone towards future advancements in hydraulic technology. The ongoing commitment of Rexroth to innovation ensures that customers remain at the forefront of hydraulic performance and application.”