Rexroth Modular Valves are pivotal components in hydraulic systems, offering precise control and efficiency. This article examines their functionalities, benefits, and applications within various industry sectors. Designed by experts at Bosch Rexroth, these valves ensure optimal performance in complex hydraulic circuits, making them essential for modern industrial solutions.

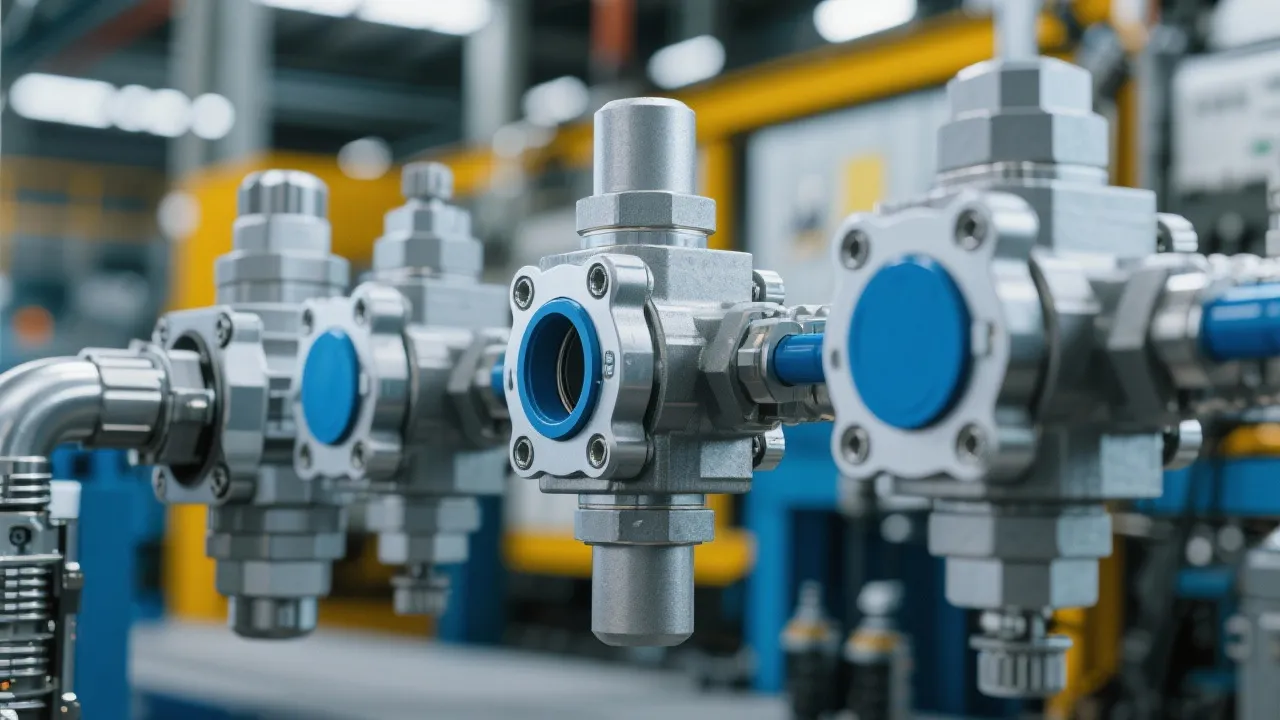

Rexroth Modular Valves, developed by Bosch Rexroth, have become a cornerstone in hydraulic systems across multiple industries. These innovative components are engineered to provide precision and efficiency in controlling fluid flow and pressure. With a design that supports seamless integration into diverse hydraulic circuits, Rexroth Modular Valves are widely recognized for their reliability and robust performance. The reputation of Bosch Rexroth spans several decades, during which the company has consistently prioritized research and development, ensuring that their products meet the evolving needs of various sectors.

The engineering principles behind Rexroth Modular Valves highlight their advanced functionality. Each valve is designed with hydraulics principles in mind, allowing for optimal performance in demanding applications. They utilize spool technology that provides seamless control over flow rate and direction. Moreover, the manufacturing process involves cutting-edge technology that ensures precision machining of each component. This attention to detail significantly reduces the risk of malfunctions and enhances overall system reliability.

The primary appeal of Rexroth Modular Valves lies in their modular design, which allows for flexibility and customization. This design facilitates easy installation and maintenance, reducing downtime and associated costs. The valves are available in various configurations, each tailored to meet specific industrial requirements. Key benefits include:

Rexroth Modular Valves are used extensively across industries such as construction, manufacturing, and agriculture. In construction, they are utilized in machinery like excavators and cranes, where their precision control is crucial for safety and efficiency. The performance of these valves helps manage heavy loads and ensures smooth operation of hydraulic systems, which is critical in reducing the risk of accidents on job sites. In manufacturing, these valves play a vital role in automation systems, providing consistent performance in processes that require exact pressure and flow control. The ability to easily adjust configurations aids in accommodating different manufacturing processes without significant downtime.

Agricultural equipment also benefits from the robust nature of Rexroth valves, which contribute to enhanced productivity in demanding field conditions. Hydraulic systems powered by these valves are more reliable, providing farmers with the efficiency they need to optimize their operations. The integration of Rexroth Modular Valves in agriculture also allows for the adoption of precision farming techniques, further enhancing yield and sustainability.

Rexroth Modular Valves are designed for quick and easy installation due to their modular layout. Installation simplicity means that technicians can swiftly integrate these valves into existing systems without the complications often associated with traditional valves, which may require specialized skills and longer timeframes.

Maintenance is another critical aspect where Rexroth Modular Valves outperform traditional valves. The modular design leads to fewer parts, and scheduled maintenance can often be performed without disassembling large sections of equipment. This not only saves time but also reduces labor costs, allowing for quicker turnarounds in production processes.

The customization capabilities of Rexroth Modular Valves are significantly higher than traditional valves, which often come in fixed configurations that limit system adaptability. Rexroth's modular approach enables businesses to configure the valve to suit the specific requirements of their hydraulic systems, accommodating any changes that may arise.

Durability is a critical consideration in hydraulic applications. Rexroth Modular Valves are designed to withstand the harshest conditions, contributing to their long lifecycle. In contrast, traditional valves may show signs of wear and tear more quickly, especially under consistent heavy loads.

| Feature | Rexroth Modular Valves | Traditional Valves |

|---|---|---|

| Installation Ease | Quick and easy due to modular design | Time-consuming, often requires more complex integration |

| Maintenance | Simple, with fewer parts needing regular replacement | Complex, may involve extensive downtime |

| Customization | High, easily tailored to specific needs | Limited, fixed configurations |

| Durability | High, designed for harsh conditions | Varied, can wear under strenuous use |

Rexroth Modular Valves' technical specifications are designed to cater to a broad spectrum of operational requirements. Key aspects include the valves' capability to handle varying pressure levels and fluid types, making them suitable for both low and high-pressure applications. Additionally, these valves incorporate advanced sealing technologies that prevent leaks and ensure consistent performance over time.

One notable technical innovation is the integration of electronically controlled hydraulics, leading to high responsiveness in system operations. This capability is particularly useful in applications requiring rapid adjustments to maintain optimal performance. Furthermore, the valves can interface with various sensor technologies, allowing for real-time monitoring and adjustments as required by the operating conditions.

The compatibility with modern control systems is another advantage, as Rexroth Modular Valves can easily be integrated into existing digital infrastructure. This ensures manufacturers can harness the power of Industry 4.0, maximizing operational efficiencies through data-driven insights. The valves' effective use of energy contributes to reduced operational costs, aligning with contemporary demands for sustainability.

Industry experts affirm that the integration of Rexroth Modular Valves can significantly boost the efficiency of hydraulic systems. This efficiency translates into reduced energy consumption and increased operational output. The longevity and reliability of these valves reduce the need for frequent repairs, offering good savings and sustainability in industrial operations.

Experts often point to case studies where companies have transitioned from traditional hydraulic systems to utilizing Rexroth Modular Valves. These case studies frequently showcase a dramatic increase in productivity alongside a marked decrease in operational costs. Insight into how businesses approach system design and integration has evolved with innovations like Rexroth Modular Valves, making it necessary for engineers to consider modular hydraulics as a robust solution to contemporary challenges.

The hydraulic industry is continually evolving, driven by advancements in technology and changing market demands. One of the significant trends affecting the future of hydraulic systems is the push towards automation and smart technologies. As industries become more digitized, the role of hydraulic systems, particularly those incorporating features such as Rexroth Modular Valves, will become even more critical.

Furthermore, as environmental concerns become more prevalent, the demand for energy-efficient hydraulic solutions will continue to rise. Engineers and manufacturers aim to design systems that minimize energy consumption and emissions. Rexroth's focus on sustainable practices through their products aligns with these market trends, ensuring they remain at the forefront of the industry.

Research is ongoing into the potential of hybrid systems that combine hydraulic and electric actuation for optimized performance. This approach can offer the benefits of both hydraulic pressure and electric precision, potentially revolutionizing applications in fields like robotics, aerospace, and automotive industries.

In summary, Rexroth Modular Valves represent a significant advancement in hydraulic technology. Their innovative design and reliable performance have set new standards in the industry, making them indispensable for businesses seeking good efficiency and adaptability in their operations. As industries continue to strive for increased productivity and sustainability, solutions like Rexroth Modular Valves will play a pivotal role in shaping the future landscape of hydraulic systems.

The commitment of Bosch Rexroth to continual improvement and customer satisfaction ensures that their modular valves will not only meet current industrial standards but also proactively address upcoming challenges in hydraulic applications. With each innovation, the reliability and versatility of Rexroth Modular Valves solidify their status as a preferred choice for engineers and operators alike across the globe.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!