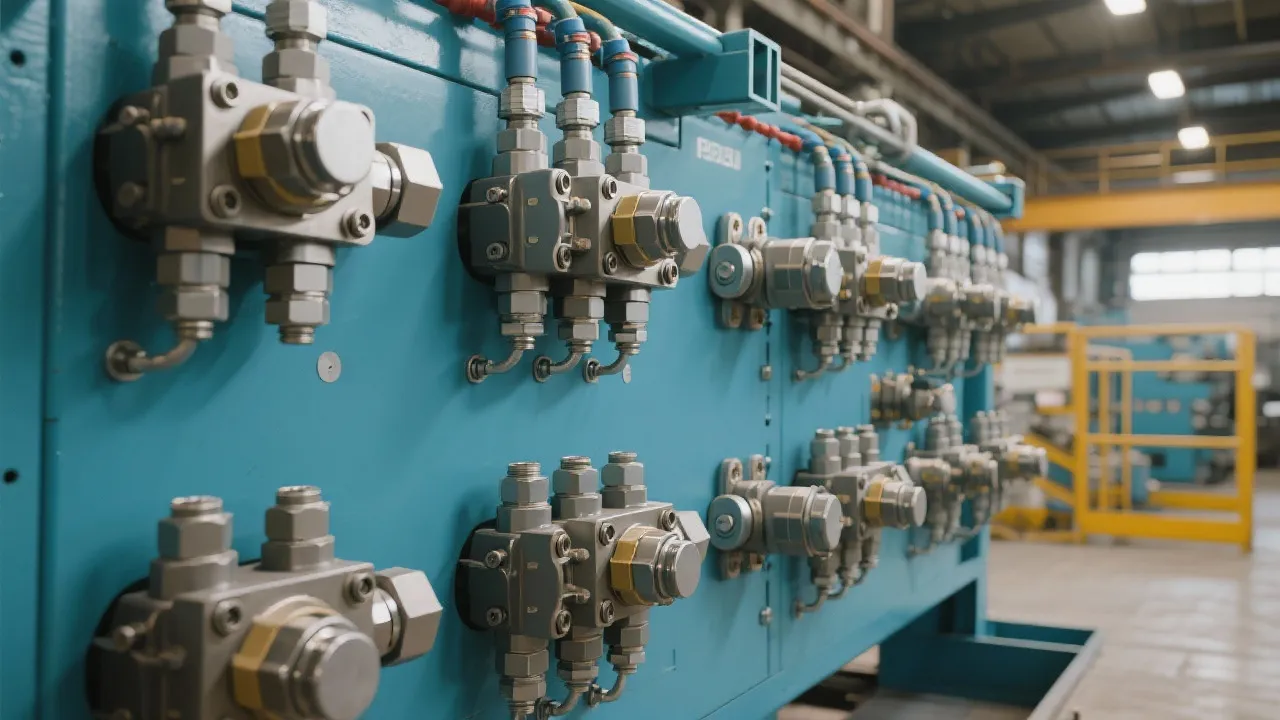

The intricacies of Rexroth Modular Valves significantly impact industrial automation efficiencies. These valves, designed for precision and adaptability, cater to various system requirements, combining engineering excellence with operational reliability. Their robust architecture supports essential hydraulic functions, crucial in diverse applications, spanning from manufacturing to energy sectors.

In the realm of industrial automation, the reliability and precision of machinery components are crucial. Rexroth Modular Valves stand out as a testament to engineering excellence, offering unparalleled performance and adaptability in various applications. These valves are integral to hydraulic systems, providing precise control and ensuring efficient operation. With the ever-increasing complexity of automation systems, choosing the right components, particularly valves, has become more critical than ever. Rexroth has leveraged its deep industry expertise to design valves that not only meet current demands but also anticipate future needs.

Rexroth Modular Valves are renowned for their robust construction and advanced functionality. These valves feature a modular design, allowing compatibility and easy integration into existing systems. The modular nature ensures that components can be customized or expanded upon as system needs evolve, which is particularly beneficial in scalable industrial environments. By allowing different configurations, they cater to a variety of applications from simple tasks to complex processes, ensuring that businesses can grow and adapt without needing to overhaul their systems regularly.

These valves are instrumental in various industrial applications, including manufacturing lines, heavy machinery, and energy production facilities. Their ability to handle different pressures and flow rates makes them indispensable in crafting bespoke solutions tailored to complex operational needs. As industries evolve, the need for adaptive and intelligent solutions has grown, making Rexroth Modular Valves increasingly relevant. Here are some specific applications:

In the manufacturing sector, Rexroth Modular Valves enhance the performance of production lines, providing the precise control necessary for tasks ranging from assembly to material handling. Their compatibility with automation technologies enables seamless connectivity, making them a staple in modern manufacturing plants. By optimizing hydraulic operations, manufacturers can achieve greater throughput and reduce operational costs, thus maintaining competitiveness in a fast-paced market.

The construction and mining industries place extreme demands on hydraulic systems due to the heavy loads and harsh environmental conditions. Rexroth Modular Valves are built to excel in such scenarios, ensuring reliable performance in equipment like excavators, bulldozers, and conveyor systems. Their durability and efficiency contribute to safer operations and lower downtime, which is critical in project timelines and budgets.

In energy production, particularly in renewable sectors such as wind and solar, the need for reliable hydraulic systems is paramount. Rexroth Modular Valves facilitate the smooth operation of machinery that can dynamically adjust to the variable nature of energy generation. With their precision control capabilities, these valves help optimize energy use and improve overall system performance, directly contributing to the efficiency of energy production systems.

In aerospace and marine applications, where safety and reliability are non-negotiable, Rexroth Modular Valves play a vital role. They are employed in hydraulic systems that operate critical functions including landing gear deployment, control surfaces, and docking systems. Their robust design and precision control are fundamental in ensuring that machinery operates as intended during all stages of operation, enhancing overall safety and reliability in these high-stakes environments.

The automotive industry has increasingly turned to modular hydraulic systems for improved assembly line operations. Rexroth Modular Valves optimize the performance of machinery used in both manufacturing and repair, offering enhanced efficiency and adaptability that facilitate just-in-time production strategies. By ensuring that hydraulic controls are precise and reliable, these valves contribute significantly to the quality and efficiency of the automotive assembly process.

| Feature | Benefit | Industry Application |

|---|---|---|

| Modular Design | Adaptable to system expansions | Manufacturing and Automation |

| High Precision | Ensures operational efficiency | Precision Engineering |

| Durable Materials | Long lifespan, low maintenance | Construction and Mining |

| Energy Efficiency | Reduced operational costs | Energy Production |

| Safety Features | Enhanced worker protection | Aerospace and Marine |

Industry experts agree that the integration of Rexroth Modular Valves can lead to notable improvements in operational efficiency and system reliability. Industrial sectors aiming at reducing downtime and enhancing productivity often opt for these well-engineered solutions. As a result, companies can expect not just performance enhancements, but also financial savings in the long term due to reduced maintenance needs. The feedback from various industries highlights the advantages of switching to modular valves for hydraulic control applications:

Real-world applications often showcase the advantages of Rexroth Modular Valves in improving operational efficiencies and system reliability. Below are a few case studies that exemplify their utility:

A major automotive manufacturer facing challenges in waste reduction and production efficiency turned to Rexroth Modular Valves to optimize their hydraulic systems. By implementing the valves, they achieved a 30% reduction in hydraulic energy consumption. This not only reduced costs but also allowed for increased production rates without the need for additional energy. The modular nature of the valves enabled seamless integration into existing equipment, minimizing displacements and disruptions during the upgrade process.

A renewable energy company sought to enhance the reliability of its hydraulic systems used in turbine operation. The introduction of Rexroth Modular Valves made a significant impact. They reported a 25% increase in operational uptime, positively affecting energy output. Additionally, the valves’ robust design withstood varying environmental conditions without requiring excessive maintenance, making them a valuable asset in the company’s operational arsenal.

A construction firm utilized Rexroth Modular Valves in their earth-moving equipment, which was regularly subjected to extreme conditions. The firm had experienced frequent equipment failures due to inadequate hydraulic control. However, after installing Rexroth valves, they noticed improved machinery performance and a 40% reduction in maintenance-related costs. The durability and precision of the valves not only extended the machinery’s life but also enabled safer operations under demanding conditions.

The landscape of hydraulic technology is continuously evolving, with innovations aimed at enhancing performance and efficiency. Several future trends stand out as particularly significant for the industry:

Rexroth Modular Valves represent a leap forward in hydraulic control technology, empowering industries with critical infrastructural support. Their role in improving process efficiencies and reducing maintenance costs cannot be overstated, making them a preferred choice in diverse industrial settings. With a commitment to innovation, Rexroth continues to advance its modular valve offerings, ensuring that they meet the evolving demands of the marketplace. By adopting these advanced components, industries can future-proof their operations, enhance productivity, and pursue new opportunities in a competitive landscape. The integration of Rexroth Modular Valves will undoubtedly play a crucial role in shaping the future of hydraulic systems in industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!