Rexroth Modular Valves are crucial components in hydraulic systems, designed for efficient flow control in industrial applications. Known for their reliability and versatility, these valves support various configurations and pressures, catering to diverse engineering needs. The article explores their function, benefits, and important selection criteria.

Introduction to Rexroth Modular Valves

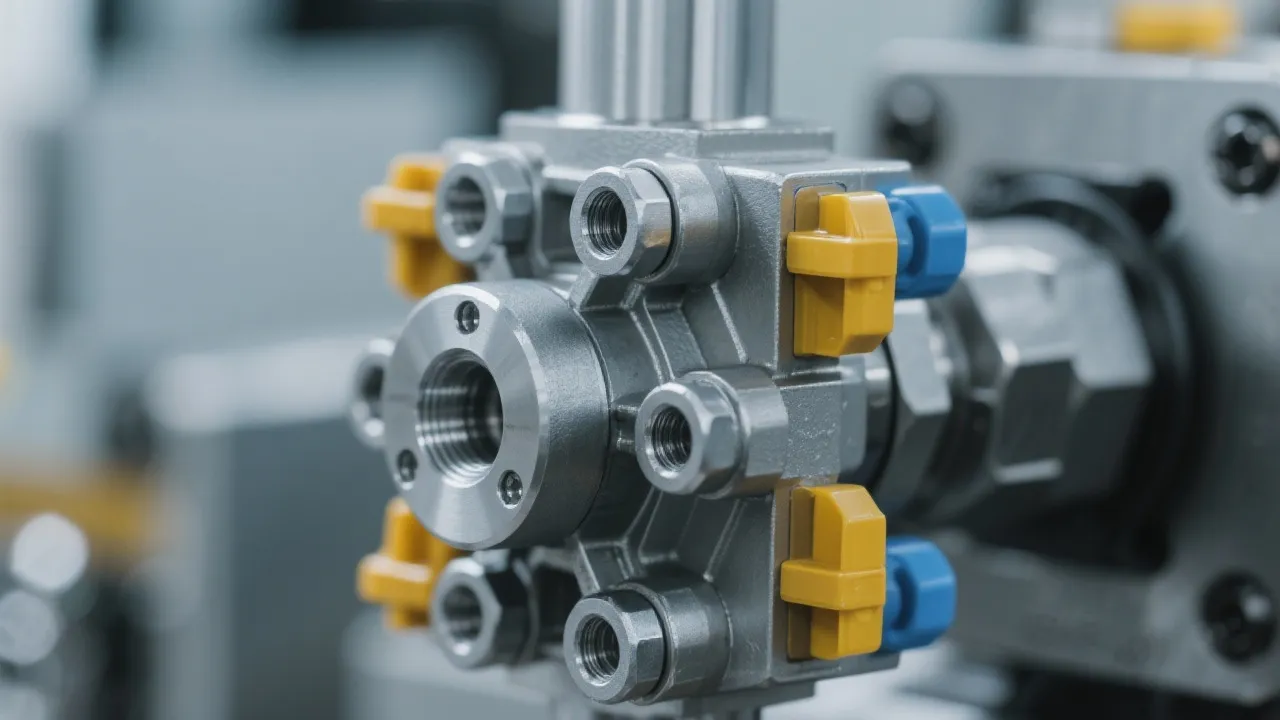

Rexroth Modular Valves, a pivotal element in modern hydraulic systems, are engineered to offer unparalleled efficiency in flow control. With their extensive integration capabilities, these valves serve diverse industrial applications ranging from manufacturing to heavy machinery. Their robust design caters to a wide array of pressure settings and system requirements, showcasing the adaptability and dependability that Rexroth is renowned for. As industries evolve and demand becomes more stringent, the role of such hydraulic components continues to grow, making them essential for maintaining operational efficiency.

Key Features of Rexroth Modular Valves

Rexroth Modular Valves stand out due to several unique features:

- Adaptability: These valves accommodate different configurations, allowing them to be customized according to specific industrial requirements. Their modularity means that users can modify systems easily to meet changing operational needs without requiring a complete redesign.

- Efficiency: Engineered for precise flow control, they minimize energy consumption and enhance overall system performance. This efficiency not only translates to energy savings but also supports sustainability initiatives by reducing carbon footprints in manufacturing processes.

- Durability: Manufactured with high-grade materials, Rexroth valves are built to withstand harsh industrial environments, ensuring long service life. This durability minimizes the need for frequent replacements, which can disrupt operations and incur additional costs.

- Versatility: They are compatible with a broad range of pressure and flow ratings, making them suitable for various applications. This versatility allows them to be seamlessly integrated into hydraulic systems across multiple industries, enhancing their functionality regardless of the context.

Applications and Benefits

These modular valves are used in numerous sectors due to their versatility. Below are some common applications and their associated benefits:

- Manufacturing: As part of automated machinery, these valves enhance the precision and repeatability of production processes. By ensuring accurate fluid control, they contribute to minimizing waste and improving product quality.

- Construction Equipment: They ensure reliability in heavy-duty applications, reducing downtime and maintenance costs. The capability to handle extreme conditions, such as temperature fluctuations and high pressures, makes them a reliable choice for construction machinery.

- Marine Systems: Their ability to control fluid flow effectively in marine equipment results in improved fuel efficiency and safety. In marine applications, these valves play a critical role in maintaining operational integrity in environments prone to corrosion and other wear factors.

- Aerospace and Aviation: In aerospace applications, Rexroth Modular Valves assist in various functions, from landing gear systems to hydraulic actuation systems, where precision and reliability are crucial. The lightweight nature and compact design of these valves also contribute to overall aircraft efficiency.

- Oil and Gas Industry: In the oil and gas sector, these valves are critical for controlling fluid and gas flow during extraction processes. Their resistance to high pressures and corrosive environments ensures optimal performance, reducing the risks associated with operational hazards.

Choosing the Right Rexroth Modular Valve

When selecting a Rexroth Modular Valve, consider the following criteria to ensure optimal performance and compatibility:

| Criteria |

Explanation |

| System Pressure Requirements |

Choose a valve that can handle the maximum pressure of your hydraulic system to avoid failure. This analysis often involves a detailed understanding of pressure spikes that could occur during operation. |

| Flow Rate |

Ensure the valve's flow capacity aligns with your system's demand to maintain efficient operation. Under-sizing can lead to inadequate system performance, while over-sizing may result in energy inefficiencies. |

| Environmental Conditions |

Select materials that withstand your specific operational environment, especially where high corrosion resistance is necessary. This consideration is especially critical for applications in maritime or chemical processing industries. |

| Mounting Options |

Consider the available space and accessibility, selecting a valve with appropriate mounting configurations. Proper installation is essential for ensuring system performance and worker safety. |

| Compatibility with Existing Systems |

Evaluate if the modular valve can work seamlessly with the current hydraulic system and components, avoiding the need for additional adjustments or equipment. |

FAQs

- What are Rexroth Modular Valves commonly used for? These valves are primarily used to control fluid flow in industrial hydraulic systems, offering reliable performance and adaptability across various applications. Their modularity allows them to be employed in everything from basic control circuits to complex automation systems.

- How do I maintain Rexroth Modular Valves? Regular inspections and adherence to maintenance schedules are essential. Ensure timely replacement of components subject to wear and check for leakages or other anomalies. Predictive maintenance strategies, incorporating technology like IoT sensors, can also enhance maintenance efficiency.

- What should I consider when installing these valves? It's crucial to follow manufacturer guidelines and standards during installation to prevent damage and ensure optimal functioning. Factors such as torque specifications and proper alignment can significantly affect the valve's performance and lifespan.

- Can these valves be used in both new and existing systems? Yes, their modular nature makes them suitable for both new installations and retrofitting into existing systems. This adaptability ensures that businesses can upgrade or expand without incurring significant costs.

Benefits of Using Rexroth Modular Valves in Automated Systems

The rise of automation in various industries has necessitated components that can reliably integrate with sophisticated control systems. Rexroth Modular Valves are particularly well-suited to this environment for several reasons:

- Seamless Digital Integration: Many Rexroth valves can be equipped with electronic controls that allow for real-time adjustments to flow rates and pressure according to the automation system’s requirements. This feature supports modern Industry 4.0 initiatives where data-driven decisions become a norm.

- Predictive Maintenance Capabilities: The integration of sensors within these valves can monitor performance metrics and provide alerts before system failures. By analyzing the data, maintenance can be performed proactively, thus minimizing unexpected downtimes.

- Improved Response Times: The ability to control flow dynamics swiftly allows for rapid adjustments in automated systems, enhancing overall operational efficiency and responsiveness to changes in production demands.

Challenges and Considerations

While Rexroth Modular Valves offer numerous advantages, there are also challenges and considerations that potential users should be aware of:

- Initial Investment: The high-quality materials and technology incorporated into Rexroth Modular Valves may present a higher initial cost compared to lower-end alternatives. However, long-term savings through increased efficiency and reduced maintenance often offset this expense.

- Complexity of Integration: Integrating hydraulic systems incorporating Rexroth Modular Valves into existing machinery can sometimes be complex. This complexity requires experienced technicians and thoughtful planning to ensure compatibility.

- Training Requirements: Staff may need training to understand and maintain advanced valve systems, particularly when new technology is involved. Investment in training programs can ensure that personnel are equipped to handle these sophisticated systems.

Future Trends in Hydraulic Valve Technology

The hydraulic valve industry is not static and is continually evolving to meet new challenges and demands. Here are some trends that are shaping the future of hydraulic valve technology:

- Increased Automation: As industries continue to invest in automation technology, the demand for modular valves that can integrate with these systems is expected to rise. Automation enhances efficiency, allowing for faster production cycles and improved accuracy.

- Smart Valves: The development of ‘smart’ valves, which are equipped with IoT capabilities, is on the rise. These valves can provide data on performance and fault conditions, enabling advanced monitoring and control systems.

- Eco-Friendly Solutions: With a growing emphasis on sustainability, manufacturers are focusing on producing hydraulic valves that minimize environmental impact. This can include using recyclable materials and designing products that consume less energy over their lifecycle.

- Modular Design Innovations: Advancements in modular design may lead to even more flexible configurations, catering to a broader range of applications. This evolution could further streamline the process of customizing hydraulic systems to specific needs.

Conclusion

Rexroth Modular Valves are a staple in modern industrial applications, providing efficiency, reliability, and flexibility. By understanding their features, applications, and selection criteria, businesses can enhance their hydraulic systems' performance and extend their operational lifespan. Whether you're implementing these valves in a new setup or upgrading existing machinery, the extensive benefits they offer make them a prudent choice for any enterprise aiming for high standards of engineering excellence. Furthermore, as industries lean towards more complex automation and smart technologies, embracing Rexroth Modular Valves positions companies not just for present needs but also for future innovations. The ongoing advancements in hydraulic systems are set to revolutionize how industries operate, ensuring that companies remain competitive while maximizing productivity and efficiency.