Atex enclosures are vital safety components in industries working with potentially explosive atmospheres. These enclosures are designed to contain electrical components, preventing ignition sources from reaching explosive elements. Compliance with Atex guidelines is crucial for ensuring operational safety in sectors such as oil, gas, and chemical manufacturing.

Atex enclosures play a pivotal role in the safety measures of industries where exposure to potentially explosive atmospheres is a constant risk. Used primarily to house electrical equipment, these enclosures are crafted with strict adherence to Atex directives to ensure they do not become sources of ignition themselves. Understanding the technical specifications and operational importance of these enclosures is essential for maintaining safety standards, especially in sectors like oil and gas, chemical processing, and pharmaceuticals. In high-risk environments, where the presence of flammable gases and dust is prevalent, Atex enclosures are indispensable tools that significantly mitigate the risk of explosions and ensure a safer working environment.

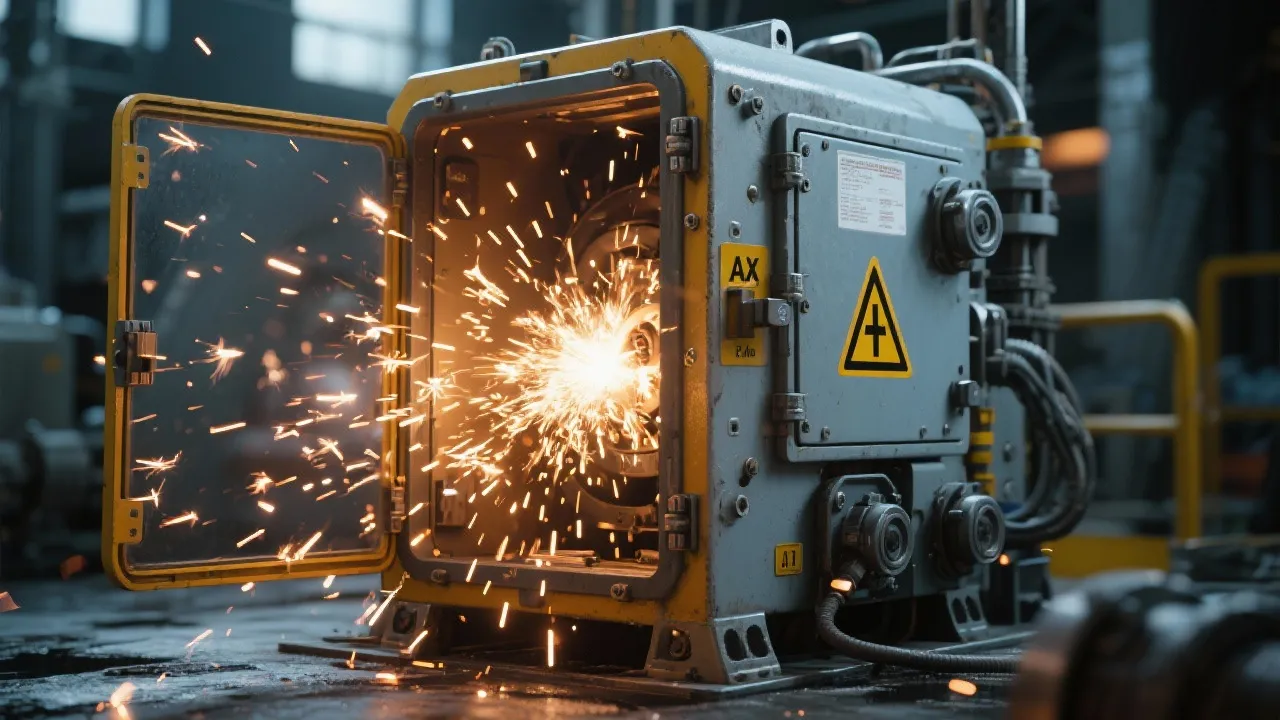

An Atex enclosure is more than just a protective casing; it is a critical safety feature designed to contain electronic components in environments where combustible gases, vapors, or dusts may be present. The enclosures prevent any internal ignition source from escaping and igniting a potential explosive atmosphere, thereby safeguarding both personnel and equipment. Industries dealing with refining processes, chemical manufacturing, and natural resource extraction rely heavily on these safe enclosures to meet regulatory compliance and protect their investments. The absence of Atex enclosures in such environments can lead to catastrophic incidents, making them not only a regulatory requirement but also a strategic necessity for operational safety.

Constructed from robust materials like stainless steel, aluminum, or high-grade plastics, Atex enclosures are built to withstand harsh conditions and protect the integrity of the housed electronics. The enclosures are tailored to meet specific industry needs, maintaining a balance between durability and functionality. Manufacturers of Atex enclosures use rigorous testing methods to ensure that the design meets the necessary safety standards, including resistance to impact, vibrations, and various environmental conditions. Atex enclosure design also incorporates features such as gaskets to ensure airtight seals, ensuring that combustible particles cannot penetrate the enclosure. Moreover, it is common for these units to undergo additional testing, such as thermal imaging, to analyze heat dissipation and identify potential hot spots that could signify a risk of ignition.

Compliance with Atex Directive 2014/34/EU is mandatory for equipment intended for use in explosive atmospheres within the European Union. This standard outlines the safety requirements for products to be used in such environments. It categorizes different zones based on the frequency and duration of explosive atmospheres, guiding the choice and design of appropriate equipment. Atex enclosures are typically marked with labels indicating their certification and specifications regarding the types of atmospheres they are designed to handle. Each enclosure is tested and certified according to these stringent standards to ensure they can successfully handle the specific risks associated with the environments they will operate in.

| Zone | Atmosphere Exposure | Requirements |

|---|---|---|

| Zone 0 | Continuous or for long periods | Equipment must ensure a high level of protection to prevent ignition. |

| Zone 1 | Occasionally present | Suitable for areas where an explosive atmosphere is likely to occur. |

| Zone 2 | Not likely to occur or only for short periods | Enclosures are suitable for less frequent exposure to hazardous conditions. |

Proper installation and regular maintenance are key to ensuring Atex enclosures continue to provide the necessary level of safety. Installation should always be performed by certified professionals familiar with the specific requirements of the installed equipment and the environment. Regular inspections and maintenance checks can identify potential wear and tear or damage, ensuring that any issues are addressed promptly to prevent safety hazards. Effective maintenance schedules can vary based on factors like the enclosure's operating environment and usage patterns, but it is generally recommended that a thorough inspection is conducted at least once every six months. During these assessments, it's important to check for corrosion, structural integrity, and the efficacy of seals and gaskets. Any identified concerns should be rectified instantly to maintain safety standards.

The implementation of Atex enclosures offers numerous benefits beyond compliance with safety regulations. They extend the lifespan of critical equipment by shielding it from harmful conditions, such as moisture, dust, and corrosive substances that may otherwise lead to premature equipment failure. Operating costs can also be reduced by minimizing the frequency of repairs and replacements, resulting in better budgetary management. Additionally, they provide peace of mind to facility managers and engineers, improving operational efficacy by minimizing downtime due to equipment failure. Properly functioning safety systems can also reduce insurance costs by mitigating risks associated with workplace accidents. Furthermore, adopting Atex enclosures can enhance a company’s reputation by demonstrating a commitment to workplace safety and environmental responsibility, which is vital in today's competitive industrial landscape.

Atex enclosures are widely used across various industries, each with unique requirements and standards. In the oil and gas sector, for example, these enclosures are crucial for maintaining safety in drilling sites, refineries, and storage facilities where explosive gases are prevalent. The chemical industry also heavily relies on Atex enclosures to protect sensitive electronic instrumentation that could otherwise contribute to chemical reactions. In pharmaceuticals, the sterile environment needed for production requires robust housing solutions to prevent contamination and ensure the integrity of products. Each application demands precise engineering to ensure the enclosure can withstand specific environmental factors, including thermal fluctuations, pressure variations, and chemical exposure.

As technology advances and industries evolve, the design and functionality of Atex enclosures are likely to develop as well. One significant trend is the integration of smart technology that allows for remote monitoring of environmental conditions within the enclosure. This enhancement can notify operators of potential risks before they become hazardous, increasing reaction times and safety protocols. Additionally, advancements in materials science could lead to even more durable and lighter enclosures that can be easily installed and maintained in challenging environments. The growing emphasis on sustainability may also prompt manufacturers to explore eco-friendly materials without compromising safety. This shift could profoundly influence how Atex enclosures are engineered, paving the way for a new generation of safety solutions.

Selecting the appropriate Atex enclosure involves a multi-step process that integrates both safety requirements and operational needs. A thorough risk assessment should be the first step, identifying potential hazards and environmental conditions specific to the intended area of use. Different parameters, such as the zone classification, ambient temperature, and type of hazardous materials present, must be considered when selecting an enclosure. Engaging with manufacturers and safety experts can provide insights into the most suitable solutions tailored for individual operations. Additionally, ensuring compatibility with existing equipment and considering future expansions or modifications is crucial to avoid costly reworks in the future.

In conclusion, understanding, selecting, and maintaining the right Atex enclosures are critical steps in ensuring workplace safety in environments prone to explosive atmospheres. As industrial safety standards continue to evolve, the role of Atex enclosures becomes increasingly significant, reflecting the industry's commitment to protecting both people and property. Given the complexity and potential consequences of explosive atmospheres, organizations must prioritize Atex enclosures as an integral component of their safety strategies. By investing in high-quality Atex solutions and adhering to strict safety protocols, industries can enhance operational efficiency while safeguarding their workforce and assets.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!