Parker actuators play a pivotal role in modern industrial systems, offering precision control and efficient energy use. These actuators are critical components in diverse sectors, supporting automation through hydraulic, pneumatic, and electromechanical solutions. This article explores their functionality, applications, and benefits in various industries.

Parker actuators, produced by the renowned Parker Hannifin Corporation, are integral to automation processes within various industrial sectors. Known for offering reliable and precise movement control, these actuators are vital in applications ranging from manufacturing to aerospace. Over the years, with advancements in technology and engineering, Parker actuators have evolved significantly, becoming more sophisticated and versatile. The emphasis on performance, reliability, and quality make these actuators essential for modern industrial practices, allowing for everything from mundane tasks to critical operations to be conducted efficiently and effectively.

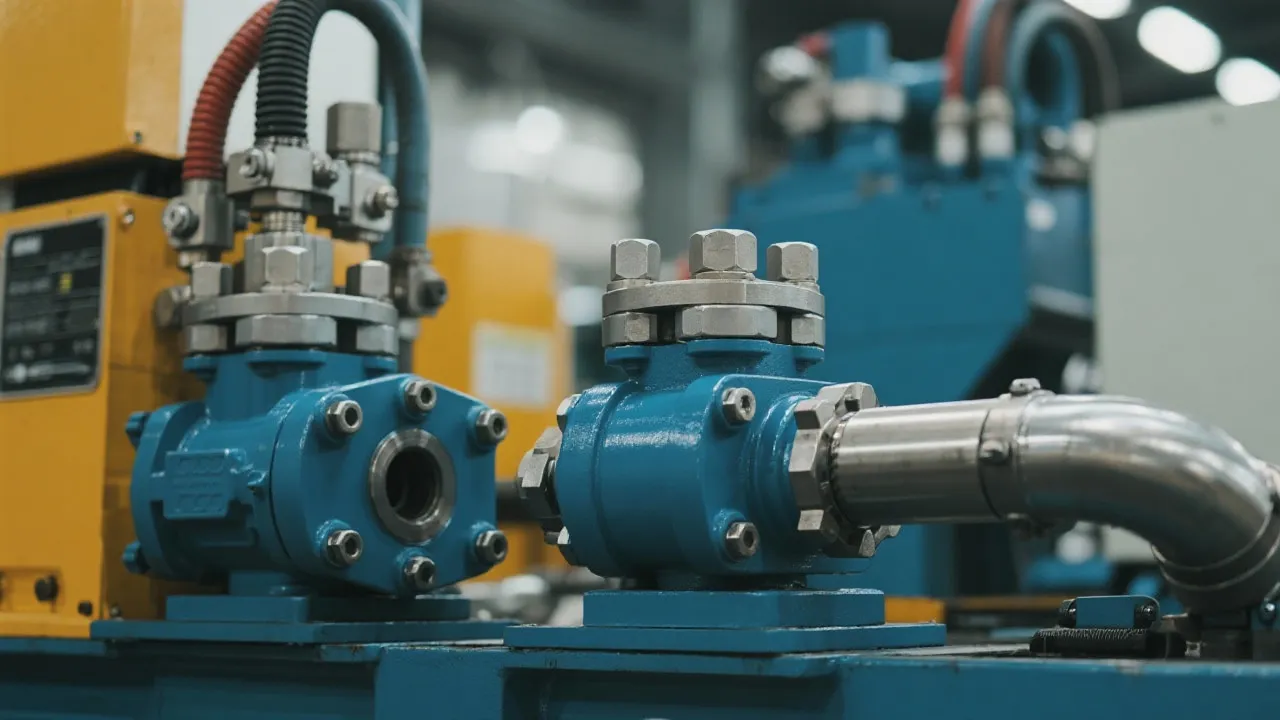

Parker actuators are distinguished by their durability and adaptability. Available in numerous configurations, including hydraulic, pneumatic, and electromechanical variations, these actuators serve to optimize performance across industries, delivering impressive power-to-weight ratios and energy efficiency. The attention to detail in design allows Parker actuators to operate under extreme conditions, providing performance consistency over time. The materials used in the construction of Parker actuators are chosen not only for strength but also for their resistance to wear, corrosion, and thermal variations. This ensures that they can function effectively in environments that can be harsh and demanding.

Parker actuators find applications in various industries, owing to their reliable performance and adaptability. The cross-sector applicability is one of their strongest selling points, allowing industries to benefit from the same high-quality components across different types of machinery and equipment:

The success of Parker actuators lies in their sophisticated design and technology. A comparison of their primary types highlights the unique advantages they offer:

| Type | Description | Advantages |

|---|---|---|

| Hydraulic Actuators | Use liquid fluid power to facilitate movement. | High force output, efficient for heavy-duty applications, and capable of precise positioning even under significant load. |

| Pneumatic Actuators | Utilize compressed air to enact movement. | Cost-effective and clean operation, ideal for lighter tasks, and generally quicker to respond, making them suitable for high-speed applications. |

| Electromechanical Actuators | Convert electrical energy into mechanical force. | Precision control, integration with electronic systems, and energy efficiency, often allowing for programmable actions that can adapt to varying conditions automatically. |

Despite their advantages, engineers and technicians may encounter challenges when integrating Parker actuators into their systems. Understanding these potential issues and their solutions can significantly enhance system performance and reliability:

Parker actuators continue to drive innovation and efficiency across industries, cementing their status as invaluable tools in the realm of industrial automation. Their ability to deliver precise, controlled, and energy-efficient motion makes them indispensable in both current applications and future technological advancements. As industries increasingly focus on automation and smart technology, the role of Parker actuators will only become more prominent. Their adaptability and commitment to quality ensure that they will remain at the forefront of automation solutions, paving the way for more efficient processes and improved productivity. As we look toward the future, we can expect Parker actuators to integrate with emerging technologies such as artificial intelligence and the Internet of Things (IoT) to further enhance their capabilities and performance in industrial settings. The continuous evolution of these actuators in response to industry needs exemplifies Parker Hannifin’s dedication to innovation; an investment in a Parker actuator is an investment into the efficiency and success of any industrial application.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!