IHM SCADA systems play a crucial role in modern industrial automation, offering real-time data acquisition, monitoring, and control capabilities. These systems integrate software and hardware to enhance operational efficiency and provide businesses with the tools needed for optimized management and oversight of complex processes.

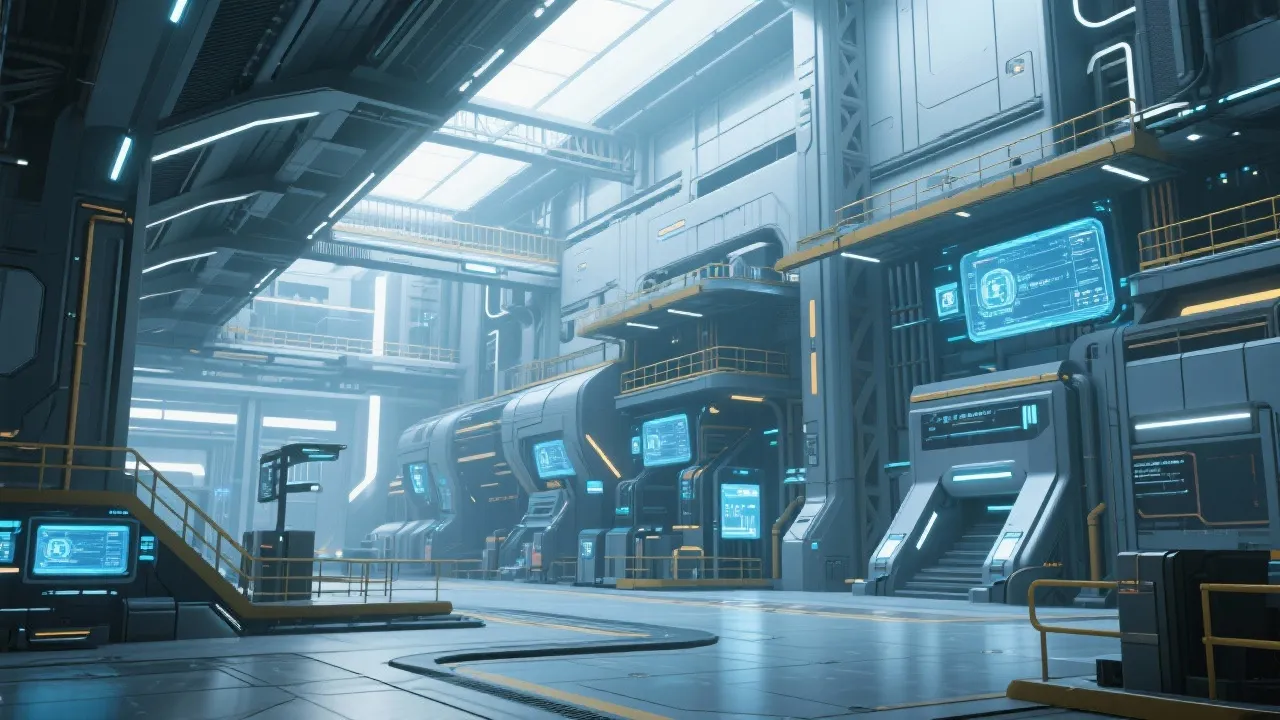

The world of industrial automation is ever-evolving, with IHM SCADA systems at the forefront of this transformation. These Supervisory Control and Data Acquisition (SCADA) systems, integrated with Interactive Human-Machine Interfaces (IHM), provide industries with sophisticated tools for detailed monitoring and management of complex operations. Their primary function is to gather real-time information and facilitate seamless communication between the system and the operator, ensuring that industrial processes are managed with precision and efficacy.

In today's competitive landscape, industries are increasingly turning to automation to enhance productivity, improve safety, and reduce operational costs. IHM SCADA systems play a crucial role in this transformation by collecting and analyzing data from various sources, allowing operators to make informed decisions swiftly. Furthermore, as industries face mounting pressure to optimize processes and minimize waste, the role of IHM SCADA systems becomes even more critical.

An IHM SCADA system typically consists of hardware and software components. The hardware includes sensors, control units, and communication devices that collect and transmit data from field devices to a central control system. The software part of the SCADA system processes this data, rendering it into a user-friendly interface for operators to interpret and act upon.

The functionality of such systems extends beyond mere monitoring. They allow for real-time process adjustments, historical data analysis, and reporting which are essential for decision-making and improving operational efficiencies. Users can access data via customizable dashboards tailored to their specific needs, ensuring that crucial information is accessible at a glance. Furthermore, with the increasing interconnectivity provided by Industry 4.0, IHM SCADA systems are becoming integral for integrating IoT devices in industrial settings.

The architecture of IHM SCADA systems often follows a tiered approach, comprising field devices, communication infrastructure, and central processing units. Field devices such as sensors, actuators, and machines collect raw data, which is transmitted across a secure communication network to a supervisory control center. Here, software applications analyze the data, enabling real-time control and monitoring functions.

The user interfaces that are part of IHM SCADA systems are incredibly sophisticated, allowing operators to visualize data trends graphically and manipulate processes intuitively. In many scenarios, customizable alarm systems notify operators of any disruptions or anomalies, enabling rapid response and preventing potential issues from escalating.

Adopting an IHM SCADA system can provide numerous advantages, including enhanced operational efficiency, improved reliability, and reduced downtime. By offering real-time data and sophisticated visualizations, operators can quickly identify and rectify process deviations, thereby increasing the overall productivity of manufacturing processes.

Moreover, these systems enhance safety and compliance by providing automated alerts and reports that ensure processes remain within permissible standards. This level of oversight is crucial for maintaining the safety of plant operations and for ensuring the reliability of the equipment in use. For instance, if a sensor detects an anomaly in temperature that exceeds safe levels, the system can immediately alert operators and implement necessary safety protocols to mitigate risk.

Furthermore, with the capacity for historical data analysis, IHM SCADA systems allow for continuous improvement in operations. By reviewing trends and performance metrics, organizations can identify areas for enhancement, optimize workflows, and implement best practices tailored to the specific needs of their industry. This process-centric approach not only leads to cost savings but also enhances product quality and service delivery.

Another significant benefit is the scalability that IHM SCADA systems offer. As industries grow or evolve, these systems can adapt to accommodate changes in production levels and operational requirements. This flexibility ensures that companies can adjust their processes without the need for complete overhauls of their existing systems, minimizing disruption and maximizing return on investment.

Selecting the appropriate IHM SCADA system for your operations involves understanding your specific industrial needs and the technological specifications of available systems. To make an informed decision, conduct a thorough analysis of your current processes and identify the key requirements your SCADA system must meet, addressing aspects such as performance, interoperability, and security.

Critical factors to consider include the compatibility of the system with existing hardware, scalability to accommodate future growth, and the availability of support and training from the supplier. It is beneficial to engage stakeholders across various departments in your organization during the selection process to ensure all needs and concerns are addressed. Collaboration between IT, operational teams, and managerial staff can lead to a more comprehensive understanding of which features will deliver the most value.

Investment in a system with a robust support framework and comprehensive training options can significantly reduce implementation time and costs, positioning your operations for success. Additionally, prioritize vendors who offer strong after-sales support and service agreements, as this can assist with ongoing maintenance and troubleshooting. Establishing a solid partnership with a technology provider can also facilitate future upgrades as technology evolves.

Moreover, consider conducting pilot tests with potential IHM SCADA solutions to evaluate their usability and effectiveness in real-world scenarios. This hands-on approach provides valuable insights into how a system will perform in your operational environment, allowing for adjustments to be made before full implementation.

| Feature | Description |

|---|---|

| Data Acquisition | Collects real-time data from sensors and field devices, ensuring that operators have immediate access to crucial information. |

| Visualization | Presents data in an intuitive, user-friendly interface, allowing operators to quickly grasp operational conditions and abnormalities. |

| Reporting | Generates analytical reports for informed decision-making, helping businesses understand trends and operational performance over time. |

| Remote Access | Enables control and monitoring from distant locations, which is particularly important in large facilities or in scenarios where personnel safety is a concern. |

| Alarm Management | Features advanced alarm management capabilities to notify operators of any deviations, facilitating rapid response and minimizing risks. |

| Scalability | Allows for easy expansion or modification of the system as organizational needs change, ensuring long-term value and system longevity. |

As industries move towards greater digital sophistication, the integration of AI, machine learning, and IoT technology within IHM SCADA systems is becoming more prevalent. These advancements offer predictive analytics capabilities, enabling systems to foresee issues before they arise and address them proactively. By utilizing historical data and real-time inputs, advanced algorithms can detect patterns associated with equipment failures, allowing organizations to address maintenance needs before they become critical, thus reducing downtime.

Moreover, the rise of edge computing allows for decentralized data processing, improving system responsiveness and reducing latency. Instead of sending all data to a central server for processing, edge computing enables analysis at or near the source of data generation. This shift not only enhances the speed of data retrieval and processing but also supports more robust data privacy and security measures as less sensitive data is sent across networks.

This evolution signifies a shift towards more intelligent, autonomous industrial ecosystems, where systems are not just reactive but are capable of self-optimization. The future of IHM SCADA systems includes the ability to learn from past events and adapt operations accordingly. Machine learning capabilities can analyze operational data trends, predict maintenance requirements, and suggest operational adjustments based on changing conditions in the manufacturing environment.

As operational environments become more interconnected, cybersecurity becomes an increasingly vital topic in IHM SCADA development. Future trends will likely focus on incorporating advanced security features, such as anomaly detection systems to identify and mitigate threats in real-time. With more devices becoming interconnected through IoT, maintaining the integrity of data and protecting the infrastructure from cyber threats will be paramount.

In conclusion, IHM SCADA systems are pivotal in advancing industrial automation. As they continue to evolve, they promise enhanced efficiency, reliability, and control over complex processes, charting a clear path towards the future of smart industries. By embracing new technologies and trends, and through strategic planning and execution, companies can leverage IHM SCADA systems to sustain competitive advantages in an increasingly dynamic market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!